Stormwater planters

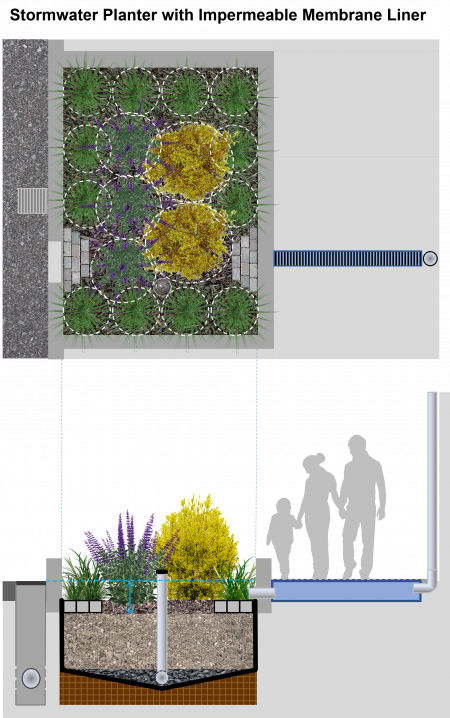

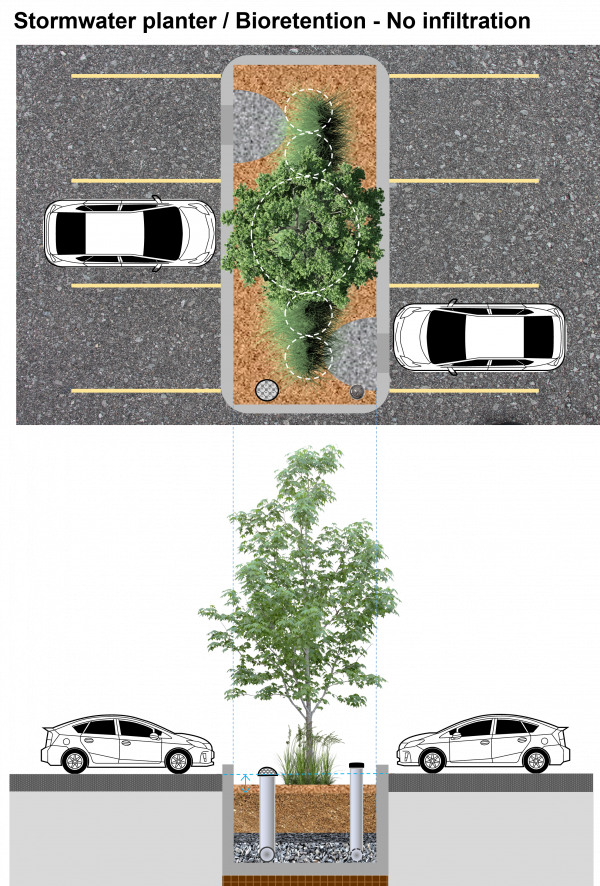

Over underground infrastructure, soils prone to subsidence, or on sites considered to be pollution hot spots, it may be necessary to prevent all infiltration. Stormwater planters are "no infiltration" or "filtration-only" BMPs, similar to bioretention cells, that can be squeezed into tight urban spaces, adjacent to buildings and within the usual setbacks required for infiltrating facilities. Stormwater planters can also be used as a means of providing building-integrated LID by capturing a portion of the rainwater from the rooftop. This type of cell can be constructed above grade in any waterproof and structurally sound container, e.g. in cast concrete or a metal tank.

Overview[edit]

Stormwater planters are an ideal technology for:

- Sites which cannot infiltrate water owing to contaminated soils or shallow bedrock,

- Zero-lot-line developments such as condos or dense urban infill.

Take a look at the downloadable Bioretention Fact Sheet below for a .pdf overview of this LID Best Management Practice:

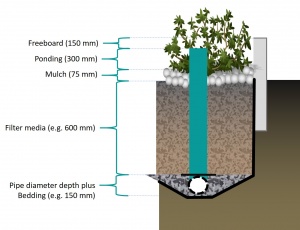

The fundamental components of a stormwater planter are:

- a planting bed of filter media,

- suitable vegetation,

- decorative aggregate or stone,

- An underdrain,

- An impermeable liner or container

The design may benefit from:

Planning Considerations[edit]

Stormwater planters may be integrated into the landscape similarly to bioretention practices. Concrete curbs or vertical-walled planter structures are common features of stormwater planter facilities. Through a study comparing the environmental impacts of bioretention systems of various design and construction material configurations, Sagrelius et al. (2022) noted that systems featuring large concrete structures (e.g., stormwater planters) incur higher environmental impacts than "soft-edged" bioretention cells when transportation-related factors associated with material production and delivery are considered. [1] See bioretention planning.

Additional site opportunities[edit]

As they do not require connection to the earth for infiltration purposes, stormwater planters can also be used in elevated locations. They are sometimes used in retrofit applications on otherwise impermeable surface, as raised beds or planters surrounding buildings. They can be employed to capture runoff from roof drains or downspouts or even upon terraces or vertical surfaces of buildings.

For more information on planning considerations and site constraints see Bioretention. For a table summarizing information on planning considerations and site constraints see Site considerations.

Design[edit]

This article is specific to flow-through stormwater planters, vegetated systems that do not infiltrate water to the native soil.

If you are designing a planted system which does infiltrate water, see advice on Bioretention: Sizing.

The dimensions of a stormwater planter are largely predetermined according to the function of the component. As they do not contain a storage reservoir the planters rely more upon careful selection of materials. Both the saturated hydraulic conductivity of the filter media and the number and size of perforations of the underdrain pipe play critical roles for flow control. Options for maintaining separation between filter media and clear stone aggregate surrounding the perforated pipe include a 100 mm deep choker layer or sheet of geotextile filter fabric.

| Component | Recommended depth (with underdrain pipe) | Typical porosity (n) |

|---|---|---|

| Ponding (dp) | 150 to 450 mm | 1 |

| Mulch | 75 ± 25 mm |

|

| Filter media (dm) |

|

|

| Choker layer | 100 mm | 0.4 |

| Perforated pipe diameter | 150 to 200 mm | 0.4 |

| Clear stone aggregate layer below perforated pipe | 50 mm (although commonly omitted altogether). | 0.4 |

Filter media[edit]

See Bioretention: Filter media

Underdrain[edit]

Stormwater planters differ from full and/or partial infiltration bioretention practices in that the storage function is provided only by the water retention capacity of the filter media. As such, there is no storage reservoir and the only purpose to the aggregate layer is to drain water to the perforated pipe. For this, a medium aggregate as described in choker layer is recommended as it negates the need for a separating layer to the filter media. Design details can be found here Underdrains for non-exfiltrating practices.

Planting[edit]

- Planters must be designed in a way that insulates the soil through freezing temperatures, or plant species that can survive the winter season in raised planters must be used.

- Stormwater planters routinely capture only rainwater flowing from adjacent rooftops. This means that salt may be less of a concern than in Bioretention: Parking lots or Bioretention: Streetscapes.

- The plant lists are still a good place to start when selecting species for LID in Ontario.

- A more formal aesthetic for the planting design is appropriate for the urban hardscape setting.

Over underground infrastructure, soils prone to subsidence, or on sites considered to be pollution hot spots, it may be necessary to prevent all infiltration. Stormwater planters are "filtration-only" BMPs, similar to bioretention cells, that can be squeezed into tight urban spaces, adjacent to buildings and within the usual setbacks required for infiltrating facilities. Stormwater planters can also be used as a means of providing building-integrated LID by capturing a portion of the rainwater from the rooftop. This type of cell can be constructed above grade in any waterproof and structurally sound container, e.g. in cast concrete or a metal tank.

Liners[edit]

An impermeable liner is incorporated into non-infiltrating practices such as stormwater planters, and may be applied in permeable pavements installations where separation from the native soils and groundwater is required.

- Waterproof containment can be created using concrete or a plastic membrane/liner (HDPE or EPDM are common materials).

- When the membrane is being used directly in the ground, punctures from stones can be prevented by compacting a layer sand (30 - 50 mm) over the soil prior to installing the membrane.

- Alternatively, a manufactured cushion fabric (geotextile) can be employed for this purpose.

- The top surface of the membrane must also be protected from stone and gravel being used for inside the BMP. Again, sand or a cushion fabric may be used.

- When a pipe is used to provide drainage from the practice to an outlet structure or storm sewer, a 'pipe boot' or flange should be sealed to both the pipe and the liner to prevent leaks.

Filter bed surface[edit]

As stormwater planters are often quite small and receive very rapid flow, both a level spreader and the use of mulch and stone to dissipate energy from concentrated inflow are strongly recommended.

Construction[edit]

Take a look at the Construction and Finishing grades and surface layer installation: vegetated LIDs pages by clicking below for further details about proper construction practices:

Inspection and Maintenance[edit]

Stormwater planters requires regular, routine inspection and maintenance of the landscaping as well as periodic inspection of other parts of the facility, especially in heavily urbanized environments. Routine maintenance should include weeding, pruning, and mulching, similar to other landscaped areas, as well as the removal of trash, debris and sediment accumulated in pretreatment areas, inlets and outlets. Watering may be needed until plant establishment (first 2 years). Periodic replacement of the top 5 cm of filter media around inlets (e.g., every 5 to 10 years) will help maintain treatment performance.

Inspections should occur twice annually (spring and late fall) and after major storm events. Inspect for vegetation density (≥ 80% coverage), damage by foot or vehicle traffic, erosion, debris, soil compaction and sediment accumulation, along with any damage to pretreatment devices.

Cleanouts and access points should be provided to allow access to the underdrain and overflow pipe. Camera inspection of these pipes should be conducted every 5 years to ensure pipes are free of roots, sediment and debris. Hydraulic flushing or root removal may be needed to clear debris or obstructions.

Take a look at the Inspection and Maintenance: Bioretention & Bioswales page by clicking below for further details about proper inspection and maintenance practices:

Gallery[edit]

Stormwater planters are ideal for situating alongside buildings to capture rainwater from roof runoff. LSRCA headquarters, 2017.

Stormwater planter, treating downspout runoff, at Waterview Rec Center, Philidelphia

Photo credit: PWDRain garden, Illick Hall, SUNY College of Environmental Science and Forestry, Syracuse, NY

Photo credit: DASonnenfeld

Performance[edit]

Hydrology[edit]

Water quality[edit]

See Also[edit]

Proprietary links[edit]

A number of precast modules exist to contain treatment media. As many of these systems are enclosed water balance calculations may be erroneous where evapotranspiration is constrained.

In our effort to make this guide as functional as possible, we have decided to include proprietary systems and links to manufacturers websites.

Inclusion of such links does not constitute endorsement by the Sustainable Technologies Evaluation Program.

Lists are ordered alphabetically; link updates are welcomed using the form below.

References[edit]

- ↑ Sagrelius, P.O., Blecken, G., Hedstrom, A., Ashley, R. 2022. Environmental impacts of stormwater bioretention systems with various design and construction components. Journal of Cleaner Production. 359 (2022) 132091. https://www.sciencedirect.com/science/article/pii/S0959652622016973?via%3Dihub

- ↑ Davis, Allen P., Robert G. Traver, William F. Hunt, Ryan Lee, Robert A. Brown, and Jennifer M. Olszewski. “Hydrologic Performance of Bioretention Storm-Water Control Measures.” Journal of Hydrologic Engineering 17, no. 5 (May 2012): 604–14. doi:10.1061/(ASCE)HE.1943-5584.0000467.

- ↑ Yeakley, J.A., and K.K. Norton. “Performance Assessment of Three Types of Rainwater Detention Structures for an Urban Development in Wilsonville, Oregon, USA,” 70. Portland, 2009.

- ↑ Macnamara, J.; Derry, C. Pollution Removal Performance of Laboratory Simulations of Sydney’s Street Stormwater Biofilters. Water 2017, 9, 907.;doi:10.3390/w9110907

- ↑ Lucke, T., & Nichols, P. W. B. (2015). The pollution removal and stormwater reduction performance of street-side bioretention basins after ten years in operation. Science of The Total Environment, 536, 784–792. https://doi.org/10.1016/J.SCITOTENV.2015.07.142

- ↑ Macnamara, J.; Derry, C. Pollution Removal Performance of Laboratory Simulations of Sydney’s Street Stormwater Biofilters. Water 2017, 9, 907. doi:10.3390/w9110907