Difference between revisions of "Filtration"

ChristineLN (talk | contribs) |

ChristineLN (talk | contribs) |

||

| Line 31: | Line 31: | ||

[[File:MaintenancePICP.png|thumb|300px|Vehicle used for vacuum maintenance of permeable pavements. ]] | [[File:MaintenancePICP.png|thumb|300px|Vehicle used for vacuum maintenance of permeable pavements. ]] | ||

[[Inspections and maintenance#Practice-specific Inspection and Maintenance|Practice-specific maintenance guides]] are available for each LID BMP. General maintenance considerations for filter-based LIDs include: | [[Inspections and maintenance#Practice-specific Inspection and Maintenance|Practice-specific maintenance guides]] are available for each LID BMP. General maintenance considerations for filter-based LIDs include: | ||

| − | *'''Inspection and maintenance frequency''': Routine inspections and maintenance are needed to assess and resolve issues, such as [[Sedimentation|sediment]] buildup. [[Maintenance, Rehabilitation and Repair|Frequency of visits]] depends on a variety of factors. LID BMP designs should include safe access for maintenance and inspection crews and confined space entry procedures should be considered for subsurface systems. [[Monitoring]] should also be undertaken to assess function. | + | *'''[[Inspections and maintenance|Inspection and maintenance frequency]]''': Routine inspections and maintenance are needed to assess and resolve issues, such as [[Sedimentation|sediment]] buildup. [[Maintenance, Rehabilitation and Repair|Frequency of visits]] depends on a variety of factors. LID BMP designs should include safe access for maintenance and inspection crews and confined space entry procedures should be considered for subsurface systems. [[Monitoring]] should also be undertaken to assess function. |

*'''Sediment removal''': Filters can become [[clogging|clogged]] with sediment, organic material, and trash, reducing flow capacity and treatment performance. When solid particles form a film on the filter's surface or accumulate within the media channels, higher pressure is needed to drive stormwater through the filter. Eventually, a point is reached at which flow through the treatment system must be redirected to another flow path (usually a bypass within or upstream of the system). Regular vacuuming or manual removal of accumulated materials is commonly required. | *'''Sediment removal''': Filters can become [[clogging|clogged]] with sediment, organic material, and trash, reducing flow capacity and treatment performance. When solid particles form a film on the filter's surface or accumulate within the media channels, higher pressure is needed to drive stormwater through the filter. Eventually, a point is reached at which flow through the treatment system must be redirected to another flow path (usually a bypass within or upstream of the system). Regular vacuuming or manual removal of accumulated materials is commonly required. | ||

*'''Media replacement''': Filter bed media can lose effectiveness over time due to clogging, chemical saturation, erosion, animal burrows, and compaction. Media may need to be replaced, regraded, or core aerated. | *'''Media replacement''': Filter bed media can lose effectiveness over time due to clogging, chemical saturation, erosion, animal burrows, and compaction. Media may need to be replaced, regraded, or core aerated. | ||

| − | *'''Overflow bypass functionality''': Ensure | + | *'''[[overflow|Overflow bypass functionality]]''': Ensure bypass structures are functioning to prevent flooding or erosion when filters are clogged or overwhelmed by large runoff events. |

==References== | ==References== | ||

Revision as of 17:21, 18 July 2025

Overview[edit]

As stormwater flows over impervious surfaces such as pavement and rooftops, it collects sediment and other pollutants before entering nearby waterways. Stormwater filtration is a key element of urban runoff management, helping to improve water quality by removing suspended solids and associated pollutants. Filtration can help achieve total suspended solids (TSS) removal targets and contributes to overall watershed health (Purvis et al., 2018).[2] Filtration works by conveying stormwater through a filter medium that captures solid particles. In most stormwater treatment systems, water is driven through the filter by a pressure difference created by gravity or hydraulic head.

Applications[edit]

Stormwater practices that use filtration as a mechanism for treatment of runoff include:

- Bioretention technologies have been shown to effectively filter sediment from parking lot, road and residential runoff (STEP, 2019).[4]

- Permeable pavements can filter runoff through the surface pores or media between pavers, as well as through the bedding and base layers. Most of the sediment directed onto the pavements is trapped near the surface where it can be more easily accessed for cleaning.

- Filtration Manufactured Treatment Devices such as the Filterra® high flow curb inlet filtration MTD have achieved 80% TSS removal during runoff events.

- Stormwater planters filter runoff through a planting bed of filter media and can be installed in tight urban spaces

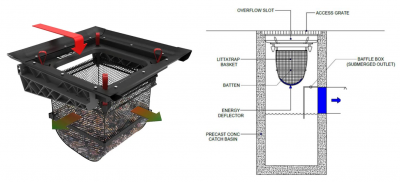

- Pretreatment options, such as vegetated filter strips and catch basin inserts

Key system design parameters[edit]

Types of filter media[edit]

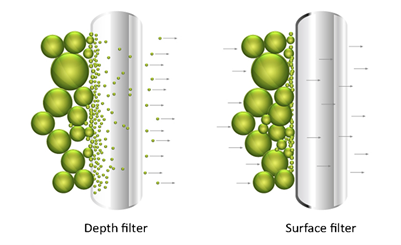

Careful consideration should be given to the type of filter media used in an LID system. Two common types of filter media used in stormwater treatment are granular media and membranes:

- Granular media is a multilayer lattice or matrix that traps solids as water flows through the tortuous channels in the media. Examples of granular media include sand and gravel.

- Membranes have very thin separation lattices with openings or pores that remove all particles larger than the nominal pore size of the filter at the surface, thereby acting much like a sieve. Membranes are often pleated to increase the surface area, allowing for more particles to be trapped prior to clogging.

Some filters include additives such as zeolite or iron to enhance the contaminant removal process for target water quality variables by increasing chemical adsorption and/or precipitation.

Sizing[edit]

When sizing filtration systems for specific sites using local historical rainfall records, several key system design parameters need to be considered. These are defined in the sizing section of the Filtration MTD page. Non-proprietary bioretention systems are sized as filters much more conservatively based on design storms, surface ponding depth and minimum media infiltration rate. The ratio of drainage area imperviousness to the surface area of bioretention facilities (referred to as the impervious-to-pervious ratio) is often many times lower than that for filtration MTDs. This ensures longer intervals for sediment maintenance and significant reductions in stormwater volumes through infiltration.

Maintenance considerations[edit]

Practice-specific maintenance guides are available for each LID BMP. General maintenance considerations for filter-based LIDs include:

- Inspection and maintenance frequency: Routine inspections and maintenance are needed to assess and resolve issues, such as sediment buildup. Frequency of visits depends on a variety of factors. LID BMP designs should include safe access for maintenance and inspection crews and confined space entry procedures should be considered for subsurface systems. Monitoring should also be undertaken to assess function.

- Sediment removal: Filters can become clogged with sediment, organic material, and trash, reducing flow capacity and treatment performance. When solid particles form a film on the filter's surface or accumulate within the media channels, higher pressure is needed to drive stormwater through the filter. Eventually, a point is reached at which flow through the treatment system must be redirected to another flow path (usually a bypass within or upstream of the system). Regular vacuuming or manual removal of accumulated materials is commonly required.

- Media replacement: Filter bed media can lose effectiveness over time due to clogging, chemical saturation, erosion, animal burrows, and compaction. Media may need to be replaced, regraded, or core aerated.

- Overflow bypass functionality: Ensure bypass structures are functioning to prevent flooding or erosion when filters are clogged or overwhelmed by large runoff events.

References[edit]

- ↑ Green Synergy Engineering. 2024. Depth vs Membrane Filter. https://www.greensynergy.my/post/depth-vs-membrane-filter

- ↑ Purvis, R. A., Winston, R. J., Hunt, W. F., Lipscomb, B., Narayanaswamy, K., McDaniel, A., Lauffer, M. S., & Libes, S. (2018). Evaluating the Water Quality Benefits of a Bioswale in Brunswick County, North Carolina (NC), USA. Water, 10(2), 134. https://doi.org/10.3390/w10020134

- ↑ Enviropod. 2022. https://www.enviropod.com/en-ca/products/littatrap

- ↑ Sustainable Technologies Evaluation Program. 2019. Comparative Performance Assessment of Bioretention in Ontario. https://sustainabletechnologies.ca/app/uploads/2019/10/STEP_Bioretention-Synthesis_Tech-Brief-New-Template-2019-Oct-10.-2019.pdf

- ↑ Contech Engineered Solutions. 2024. Filterra Vault Owner’s Manual. https://www.conteches.com/media/wlrdhu4w/filterra-vault-om.pdf