Difference between revisions of "Bioretention"

Jenny Hill (talk | contribs) |

Jenny Hill (talk | contribs) |

||

| Line 23: | Line 23: | ||

*For optimal performance bioretention facilities should receive runoff from between 5 to 20 times their own surface area. | *For optimal performance bioretention facilities should receive runoff from between 5 to 20 times their own surface area. | ||

*In the conceptual design stage it is recommended to set aside approximately 10 - 20 % of a catchment area to the bioretention facility. | *In the conceptual design stage it is recommended to set aside approximately 10 - 20 % of a catchment area to the bioretention facility. | ||

| − | *Bioretention | + | *Bioretention cells work best when distributed, so that no one facility receives runoff from more than 0.8 Ha. |

:Although, there is a trade off to be considered regarding distributed collection and treatment against ease of maintenance. | :Although, there is a trade off to be considered regarding distributed collection and treatment against ease of maintenance. | ||

*Bioretention can be almost any shape, from very curving, soft edges with variable depth, to angular, hard sided and uniform depth. | *Bioretention can be almost any shape, from very curving, soft edges with variable depth, to angular, hard sided and uniform depth. | ||

Revision as of 00:55, 22 September 2017

This article is about planted installations designed to capture and filter surface runoff through engineered soil (filter media).

For simple systems (typically without regulatory control), see Rain gardens.

For linear systems, which convey flow, but are otherwise similar see Bioswales.

Overview[edit]

Bioretention cells are one of the most well recognized form of low impact development (LID). They can fit into any style of landscape and encompass all mechanisms of action: infiltration, filtration and evapotranspiration.

Bioretention cells are an ideal technology for:

- Fitting functional vegetation into urban landscapes

- Treating runoff collected from nearby impervious surfaces

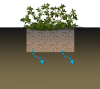

The fundamental components of a bioretention cell are:

- A 'filter bed' containing an engineered soil mix

- A storage layer of coarse aggregate

- Planting and a finishing surface layer (e.g. mulch)

Additional components may include:

- An underdrain to redistribute or remove excess water

- An impermeable membrane to prevent infiltration to soils below

Planning considerations[edit]

Space

- For optimal performance bioretention facilities should receive runoff from between 5 to 20 times their own surface area.

- In the conceptual design stage it is recommended to set aside approximately 10 - 20 % of a catchment area to the bioretention facility.

- Bioretention cells work best when distributed, so that no one facility receives runoff from more than 0.8 Ha.

- Although, there is a trade off to be considered regarding distributed collection and treatment against ease of maintenance.

- Bioretention can be almost any shape, from very curving, soft edges with variable depth, to angular, hard sided and uniform depth.

- For ease of construction and to ensure that the vegetation has adequate space, cells should be no narrower than 0.6 m at any point.

- The maximum width of a facility is determined by the reach of the construction machinery, which must not be tracked into the cell.

Infiltration

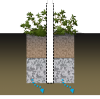

Some form of stormwater landscaping (bioretention) can be fitted into most spaces. One of the key decisions is whether to infiltrate all of some of the collected water into the native soil. Although there are some constraints to infiltrating water, it is preferable to do so where possible. Partial infiltration facilities are a popular choice over 'tight' soils (infiltration ≤ 15 mm/hr).

| Type | Gravel layer | Underdrain | Liner | Mechanisms | Schematic |

|---|---|---|---|---|---|

| Rain gardens | - | - | - | These are the simplest construction, often used by residents or community groups. Volume reduction is through infiltration and evapotranspiration. |

|

| Infiltrating bioretention | yes | - | - | This is a highly desirable type of bioretention where the soils permit infiltration at a great enough rate to empty the facility between storm events. Volume reduction is primarily through infiltration to the underlying soils, with some evapotranspiration. As there is no outflow from this BMP, it is particularly useful in areas where nutrient management is a concern to the watershed. |

|

| Partially infiltrating bioretention | yes | yes | - | Including an underdrain in the gravel storage layer help to empty the facility between storm events, even over ‘tight soils’. The drain discharges to a downstream point, which could be an underground infiltration facility. Limited volume reduction is gained through infiltration and evapotranspiration. By raising the outlet of the discharge pipe the bottom portion of the BMP can only drain through infiltration. This creates a fluctuating anaerobic/aerobic environment which promotes denitrification. Increasing the period of storage has benefits for promoting infiltration, but also improves water quality for catchments impacted with nitrates. A complimentary technique is to use fresh wood mulch, which also fosters denitrifying biological processes. |

|

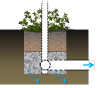

| Biofilters (non-infiltrating) |

yes | yes | yes | This type may be required over contamination hot-spots or in very dense urban areas with a lot of other underground infrastructure. The design includes an impermeable base and sides, so that volume reduction is made only through evapotranspiration. This type of cell can be constructed above grade in any waterproof and structurally sound container, e.g. in cast concrete or a metal tank. |

|

Inlets and pretreatment options

Options for pretreatment include:

- A gravel diaphragm for sheet flow

- Vegetated filter strips for sheet flow

- A forebay for concentrated overground flow

- An oil and grit separator for concentrated underground flow

Simple (non-treating) inlets include:

- Sheet flow from a depressed curb

- One of more curb cuts

- Covered drains

Overflow routing

Routing[edit]

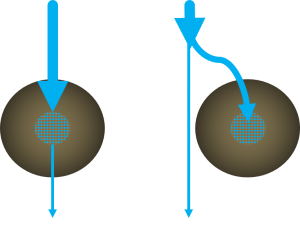

- Infiltration facilities can be designed to be inline or offline from the drainage system. See figure to the right for an illustration.

- Inline facilities accept all of the flow from a drainage area and convey larger event flows through an overflow outlet. The overflow must be sized to safely convey larger storm events out of the facility. The overflow must be situated at the maximum surface ponding elevation or furthest downgradient end of the facility to limit surface ponding during periods of flow in excess of the facility storage capacity.

- Offline facilities use flow splitters or bypass channels that only allow the design storm runoff storage volume to enter the facility. Higher flows are conveyed to a downstream storm sewer or other BMP by a flow splitting manhole weir or pipe, or when the maximum surface ponding depth has been reached, by by-passing the curb opening and flowing into a downstream catchbasin connected to a storm sewer.

Overflow Elevation[edit]

The invert of the overflow should be placed at the maximum water surface elevation of the practice (i.e. the maximum surface ponding level). A good starting point is 150 to 350 mm above the surface of the mulch cover. However, consideration should be given to public safety, whether or not an underdrain is included, the time required for ponded water to drain through the filter bed surface, and if no underdrain is present, into the underlying native soil (must drain within 48 hours). See Bioretention: Sizing and Stormwater planters for more details.

Freeboard[edit]

- In swales conveying flowing water a freeboard of 300 mm is generally accepted as a good starting point.

- In bioretention the freeboard is the difference between the invert elevation of the inlet and overflow structure. 150 mm will usually suffice, so long as the inlet will not become inundated during design storm conditions.

- In above grade stormwater planters, the equivalent dimension would be the difference between the invert elevation of the lip of the planter and the overflow structure (150 mm minimum).

Overflow Outlet Options[edit]

Metal grates are recommended (over plastic) in all situations.

| Feature | Anti Vandalism/Robust | Lower Cost Option | Self cleaning |

|---|---|---|---|

| Dome grate | x | ||

| Flat grate | x | ||

| Catch basin | x | ||

| Ditch inlet catch basin | x | x | |

| Curb cut | x | x | x |

Gallery[edit]

Flat metal overflow with stone surround to reduce erosion around the cast concrete structure. Mississauga Road, ON

Domed, metal overflow grate. Being flush with the surface reduces potential infiltration of ponded water. Photo credit: Aaron Volkening

Overflow inlet for newly constructed stormwater bioretention areas in median of Bradley Road. Village of Brown Deer, Wisconsin. Bradley Road, east of 51st Street. Photo from October 2015. Constructed summer 2015.

Photo credit: Aaron Volkening

Design for maintenance

Design[edit]

Sizing

Bioretention cells should be sized to accommodate runoff from approximately 5 to 20 times the footprint area of the facility. i.e. I/P ratio of 5 to 20. Equations and a tool to help with sizing infiltration practices

Construction[edit]

Incentives and Credits[edit]

In Ontario

City of Mississauga

The City of Mississauga has a stormwater management credit program which includes RWH as one of their recommended site strategies [1].

LEED BD + C v. 4

Sustainable sites: Rainwater management (up to 3 points)

- Two points (or 1 point for Healthcare) will be awarded if the project manages "the runoff from the developed site for the 95th percentile of regional or local rainfall events."

- Three points (or 2 points for Healthcare) will be awarded if the project manages "the runoff from the developed site for the 98th percentile of regional or local rainfall events."

OR

- For zero-lot-line projects only, 3 points (or 2 points for Healthcare) will be awarded if the project manages "the runoff from the developed site for the 85th percentile of regional or local rainfall events."