Difference between revisions of "Underdrains"

Jenny Hill (talk | contribs) |

Jenny Hill (talk | contribs) |

||

| Line 6: | Line 6: | ||

*At least one pair of vertical cleanout pipes/wells should be included in the design, for inspection and periodic flushing of accumulated sediment. As most hydro-jetting apparatus used for this has some trouble accommodating narrow 90 deg bends, it is important that both ends of a perforated pipe be connected with a pair of 45 deg elbows/Y connectors instead. | *At least one pair of vertical cleanout pipes/wells should be included in the design, for inspection and periodic flushing of accumulated sediment. As most hydro-jetting apparatus used for this has some trouble accommodating narrow 90 deg bends, it is important that both ends of a perforated pipe be connected with a pair of 45 deg elbows/Y connectors instead. | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |+Clean out spacing | + | |+Clean out spacing<ref>Province of Ontario. (2018). O. Reg. 332/12: BUILDING CODE. Retrieved February 23, 2018, from https://www.ontario.ca/laws/regulation/120332<ref> |

|- | |- | ||

! Pipe internal diameter (mm) | ! Pipe internal diameter (mm) | ||

Revision as of 16:26, 7 March 2018

Underdrains comprise a length of perforated pipe embedded into a layer of reservoir aggregate. They are an optional component of bioretention systems, stormwater planters, swales and tree wells. Their design varies according to the drainage requirements of the installation, and the available maintenance access.

Underdrains for infiltrating practices[edit]

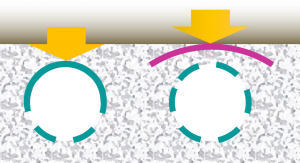

The pipe within the drain should be elevated from the base to promote infiltration of the water stored beneath. The depth of this internal water storage should be sized according to the desired drainage time and the infiltration rate of the native soils below. An alternative design configuration permits the head of water to be stored by using an upturned outflow pipe.

- At least one pair of vertical cleanout pipes/wells should be included in the design, for inspection and periodic flushing of accumulated sediment. As most hydro-jetting apparatus used for this has some trouble accommodating narrow 90 deg bends, it is important that both ends of a perforated pipe be connected with a pair of 45 deg elbows/Y connectors instead.

| Percent soil/filter media passing 0.075 mm (#200 sieve) | Non-woven fabric apparent opening size (AOS, mm) | Woven fabric percent open area (POA, %) | Permittivity (sec-1) |

|---|---|---|---|

| >85 | ≤ 0.3 | - | 0.1 |

| 50 - 85 | ≤ 0.3 | ≥ 4 | 0.1 |

| 15 - 50 | ≤ 0.6 | ≥ 4 | 0.2 |

| 5 - 15 | ≤ 0.6 | ≥ 4 | 0.5 |

| ≤ 5 | ≤ 0.6 | ≥ 10 | 0.5 |

Performance research[edit]

http://www.mdpi.com/2073-4441/7/4/1595/htm

Alternative Technology[edit]

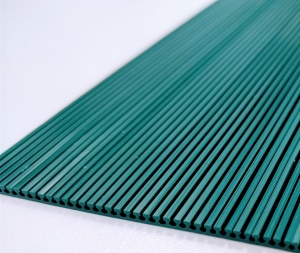

Smart drain is a polymer ribbon-like material with capillary drains on the underside; it's use has recently been demonstrated in bioretention[9]. It's low profile may make it particularly well suited to non-infiltrating practices, such as Stormwater planters.

- ↑ W.H. van der Molen en J.Wesseling, 1991. A solution in closed form and a series solution to replace the tables for the thickness of the equivalent layer in Hooghoudt's drain spacing equation. Agricultural Water Management 19, pp.1-16

- ↑ van Beers, W.F.J. 1976, COMPUTING DRAIN SPACINGS: A generalized method with special reference to sensitivity analysis and geo-hydrological investigations, International Institute for Land Reclamation and Improvement (ILRI) Wageningen, The Netherlands

- ↑ Hazenberg, G., and U. S. Panu (1991), Theoretical analysis of flow rate into perforated drain tubes, Water Resour. Res., 27(7), 1411–1418, doi:10.1029/91WR00779.

- ↑ Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017

- ↑ 5.0 5.1 5.2 Judge, Aaron, "Measurement of the Hydraulic Conductivity of Gravels Using a Laboratory Permeameter and Silty Sands Using Field Testing with Observation Wells" (2013). Dissertations. 746. http://scholarworks.umass.edu/open_access_dissertations/746

- ↑ Newman AP, Coupe SJ, Spicer GE, Lynch D, Robinson K. MAINTENANCE OF OIL-DEGRADING PERMEABLE PAVEMENTS: MICROBES, NUTRIENTS AND LONG-TERM WATER QUALITY PROVISION. https://www.icpi.org/sites/default/files/techpapers/1309.pdf. Accessed July 17, 2017.

- ↑ Paul P, Tota-Maharaj K. Laboratory Studies on Granular Filters and Their Relationship to Geotextiles for Stormwater Pollutant Reduction. Water. 2015;7(4):1595-1609. doi:10.3390/w7041595.

- ↑ ONTARIO PROVINCIAL STANDARD SPECIFICATION METRIC OPSS 1860 MATERIAL SPECIFICATION FOR GEOTEXTILES. 2012. http://www.raqsb.mto.gov.on.ca/techpubs/OPS.nsf/0/2ccb9847eb6c56738525808200628de1/$FILE/OPSS%201860%20Apr12.pdf. Accessed July 17, 2017

- ↑ Redahegn Sileshi; Robert Pitt, P.E., M.ASCE; and Shirley Clark, P.E., M.ASCE Performance Evaluation of an Alternative Underdrain Material for Stormwater Biofiltration Systems, Journal of Sustainable Water in the Built Environment, 4(2), May 2018 https://doi.org/10.1061/JSWBAY.0000845