Difference between revisions of "Wetlands"

ChristineLN (talk | contribs) |

ChristineLN (talk | contribs) |

||

| Line 207: | Line 207: | ||

==Inspections and Maintenance== | ==Inspections and Maintenance== | ||

| − | |||

| − | Like all LID systems, [[Inspections and maintenance#Construction Inspections|construction]] and [[Inspections and maintenance#Assumption Inspections|assumption]] inspections should be undertaken during building and handover of constructed wetlands. | + | <div style="overflow: hidden;"> |

| + | |||

| + | <div style="float: right; padding-left: 20px; padding-bottom: 10px;"> | ||

| + | <pdf width="450" height="600">File:SWMFG2016 Guide April-2018.pdf</pdf> | ||

| + | </div> | ||

| + | |||

| + | Constructed wetlands need to be regularly inspected and maintained to ensure that the system is meeting the intended level of treatment. Like all LID systems, [[Inspections and maintenance#Construction Inspections|construction]] and [[Inspections and maintenance#Assumption Inspections|assumption]] inspections should be undertaken during building and handover of constructed wetlands. | ||

| + | |||

[[Inspections and maintenance#Routine Operation Inspections|Routine operation inspections]] and preventative maintenance for the lifespan of constructed wetlands should cover: | [[Inspections and maintenance#Routine Operation Inspections|Routine operation inspections]] and preventative maintenance for the lifespan of constructed wetlands should cover: | ||

| − | *Review as-built drawings, maintenance history, and prepare inspection form prior to site visit | + | * Review as-built drawings, maintenance history, and prepare inspection form prior to site visit |

| − | *Ease of access for inspections | + | * Ease of access for inspections |

| − | *Vegetation management - grass mowed to a height greater than | + | * Vegetation management - grass mowed to a height greater than 4–6" and clippings collected, invasive species monitoring and control |

| − | *Repair of vandalized areas | + | * Repair of vandalized areas |

| − | *Sediment accumulation | + | * Sediment accumulation |

| − | *Mechanical equipment check | + | * Mechanical equipment check |

| − | *Structural component check | + | * Structural component check |

| + | |||

| − | A field data sheet for the inspection of constructed wetlands is available below. You can download (downward facing arrow on the top righthand side) and print ( | + | A field data sheet for the inspection of constructed wetlands is available below. You can download (downward facing arrow on the top righthand side) and print (Printer emoticon on top right hand side) the Wetland Maintenance and Inspection Form developed by Toronto and Region Conservation Authority (TRCA) and CH2M Hill Canada. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | Functional, performance, and environmental effects [[Monitoring|monitoring]] can help determine the frequency of routine maintenance and identify the need for more extensive corrective maintenance. Most major [[Inspections and maintenance#Forensic Inspection and Testing (FIT)|corrective maintenance]] for constructed wetlands fall into: | ||

| + | * major structural repair | ||

| + | * bank stabilization | ||

| + | * sediment removal | ||

| + | * unplugging of inlets and outlets | ||

| − | + | </div> | |

==Gallery== | ==Gallery== | ||

Revision as of 14:29, 17 July 2025

Overview[edit]

Free-water surface flow wetlands are most commonly employed for stormwater treatment and are similar to SWM ponds in function and design. The most significant difference between ponds and wetlands is the extent to which they incorporate shallow zones for wetland plants. A facility is normally characterized as a wetland if shallow zones (<0.5 m deep) make up more than 70 % of its volume.

Wetlands can contribute to[1]:

- Enhanced biodiversity

- Recreational opportunities and a more aesthetic aquatic landscape

- Improved water quality and achieving TSS targets

- Flood attenuation

Case studies are available for wetlands used in LID systems.

Planning considerations[edit]

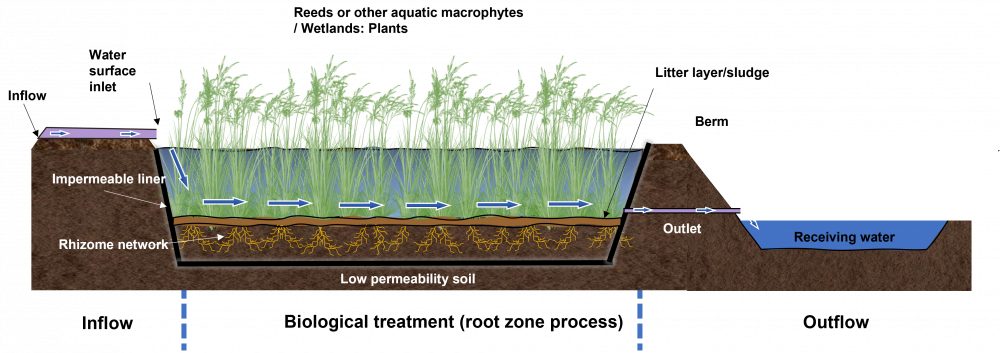

Wetlands differ based on how water travels through the system. Free-water surface flow wetlands have water exposed on the surface, which provides excellent water quality treatment but may pose health and safety risks. Sub surface flow systems provide generally lower health and safety risks and are sometimes employed to handle stormwater in combination with another wastewater stream. In horizontal sub-surface flow wetlands, water flows horizontally through a media bed, while in vertical sub-surface flow wetlands, water is introduced at the surface and percolates vertically through the media.

| Free-water surface flow | Horizontal sub-surface flow | Vertical sub-surface flow |

|---|---|---|

|

|

|

Pros

|

Pros

|

Pros

|

Cons

|

Cons

|

Cons

|

Design[edit]

Sizing free-water[edit]

| Element | Design Objective | Criteria |

|---|---|---|

| Drainage Area | Sustaining vegetation, volumetric turnover | 5 Ha (≥10 Ha preferred) |

| Treatment Volume | Provision of appropriate level of protection | See below |

| Active Storage | Detention | Suspended solids settling 24 hrs (12 hrs if in conflict with min. orifice size) |

| Forebay | Pre-treatment |

|

| Length-to-Width Ratio | Maximize flow path and minimize short-circuiting potential |

|

| Permanent pool depth | Vegetation requirements, rapid settling | The average permanent pool depth should range from 150 mm to 300 mm |

| Active storage depth | Storage/flow control, sustaining vegetation | Maximum 1.0 m for storms < 10 year event |

| Side slopes (See also berms) | Safety |

|

| Inlet | Avoid clogging/freezing |

|

| Outlet (See also flow control) | Avoid clogging/freezing |

|

| Maintenance access | Access for backhoes or dredging equipment |

|

| Buffer | Safety | Minimum 7.5 m above maximum water quality/erosion control water level |

| Performance level | Storage volume (m3/Ha) required according to catchment impervious cover | |||

|---|---|---|---|---|

| 35% | 55% | 70% | 85% | |

| 80 % TSS removal | 80 | 105 | 120 | 140 |

| 70 % TSS removal | 60 | 70 | 80 | 90 |

| 60 % TSS removal | 60 | 60 | 60 | 60 |

Modeling sub-surface[edit]

SubWet 2.0 is a modeling tool for sub-surface flow wetlands (both 100% constructed and naturalized/adapted). It can be used to simulate removal of nitrogen (including nitrogen in ammonia, nitrate and organic matter), phosphorus and BOD5 in mg/l and the corresponding removal efficiencies (in %). Although the model has been calibrated already with data from cold and warm climates, users can further calibrate and validate it using local data observations.

Materials[edit]

- For planting recommendations, see Wetlands: Plants

Performance[edit]

Relative to a wet pond, a constructed wetland may offer added pollutant removal benefits due to enhanced biological uptake and the filtration effects of the vegetation. Early stage wetlands readily sorb phosphorus onto substrates and sediments. Phosphorus removal in wetland systems is usually carried out by incorporating alum sedimentation ponds or sand filters as cells of the system, and/or by polishing wetland effluent in an iron-dosed mechanical filter.[6]

Freezing temperatures in winter and early spring can reduce treatment if the wetland either freezes solid or a cover of ice prevents the water from entering the wetland. If under-ice water becomes confined, water velocities may increase, thereby reducing contact times[3]. Runoff in excess of maximum design flows should be diverted around the wetland to avoid excessive flows through the wetland.

STEP (under previous name SWAMP) conducted their own research into the performance of stormwater wetlands, the project page and report can be viewed here.

Central Lake Ontario Conservation Authority have been undertaking a coastal wetland monitoring project across Durham region, see here.

Inspections and Maintenance[edit]

Gallery[edit]

Emergent wetland vegetation supported by stormwater runoff at Kino Environmental Restoration Project. Photo by Matthew Grabau, US Fish and Wildlife Service

Azalea Park, Charlottesville VA - "This side of the park, formerly located along a runoff channel that led into Moore's Creek, has been converted into a wetland which supports a surprising amount of insect and amphibian life." -Credit and Photo: Scott Clark (certhia on Flickr).

See also[edit]

External links[edit]

- Ontario's wetland conservation strategy

- Centre for Advancement of Water and Wastewater Technologies at Fleming College

Articles for review[edit]

- Kennedy, G., and T. Mayer. 2002. Natural and Constructed Wetlands in Canada: An Overview. Water Qual. Res. J. Canada 37(2): 295–325. doi: 10.2166/wqrj.2002.020.

- Bendoricchio, G., L. Dal Cin, and J. Persson. 2000. Guidelines for free water surface wetland design. EcoSys Bd 8: 51–91. http://www.pixelrauschen.de/wet/design.pdf (accessed 9 May 2018).

- ↑ Toronto and Region Conservation Authority. 2025. Wetlands. https://trca.ca/conservation/restoration/wetlands/#:~:text=Increased%20biodiversity,as%20bird%20watching%20and%20fishing

- ↑ Grant, N., M. Moodie, and C. Weedon. 2000. Sewage Treatment Solutions. p. 35–67. In Sewage Solutions: Answering the Call of Nature. Centre for Alternative Technology Publications.

- ↑ 3.0 3.1 United States Environmental Protection Agency. 1995. A HANDBOOK OF CONSTRUCTED WETLANDS: A guide to creating wetlands for agricultural wastewater, domestic wastewater, coal mine drainage and stormwater.

- ↑ Jacques Whitford Consultants, 2008. CONSTRUCTED & ENGINEERED WETLANDS p. 1-21

- ↑ 5.0 5.1 Toronto and Region Conservation Authority (TRCA), and CH2M Hill Canada. 2018. Inspection and Maintenance Guide for Stormwater Management Ponds and Constructed Wetlands (T van Seters, L Rocha, and K Delidjakovva, Eds.).

- ↑ Jacques Whitford Consultants, 2008. CONSTRUCTED & ENGINEERED WETLANDS p. 1-21