Difference between revisions of "Oil and Grit Separator"

(→Sizing) |

|||

| Line 112: | Line 112: | ||

</br> | </br> | ||

| − | [[File:Surface loading groups 1 & 2 OGS Update.png| | + | [[File:Surface loading groups 1 & 2 OGS Update.png|800px]]<br> |

</br> | </br> | ||

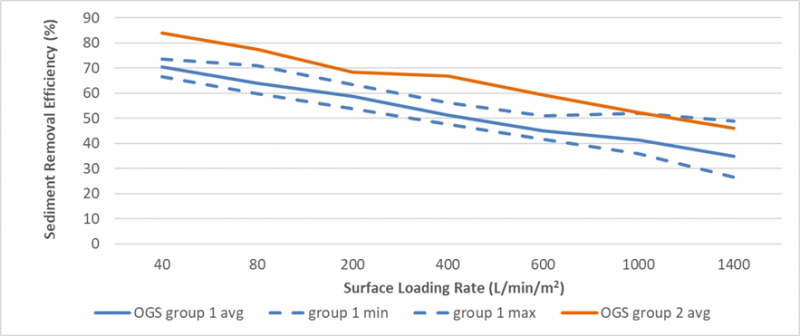

'''''Graph Above''''': Sediment removal efficiencies for ISO 14034 verified OGS. '''Group 1''' units (n=10) are conventional OGS with large openings.<br> | '''''Graph Above''''': Sediment removal efficiencies for ISO 14034 verified OGS. '''Group 1''' units (n=10) are conventional OGS with large openings.<br> | ||

Revision as of 16:16, 6 February 2024

Overview[edit]

Oil and Grit Separators (OGS) are Manufactured Treatment Devices (MTDs) used for water quality treatment of stormwater runoff through the removal of large particle suspended solids and associated pollutants, and debris. Some devices can also trap light liquids such as oil and other floatables. These MTDs are typically installed underground within the stormwater sewer system in an on-line or off-line configuration. They are distinguished from Filtration-based MTDs by their removal of solids through settling rather than filtration.

Application[edit]

Oil and Grit Separators are suitable as pre-treatment to other downstream treatment systems such as ponds or LID features. Cost effective application of OGS as pretreatment to a downstream LID practice typically requires that the practice have a single inlet with a drainage area larger than 0.2 ha.

OGS normally require maintenance every year to function as designed. The cost and level of effort required to undertake the maintenance program over the full life cycle of OGS should be carefully considered when implementing this water quality treatment solution.

Further guidance on how the data and information generated from verified laboratory testing of OGS technologies should be interpreted and factored into regulatory agency approvals and procurement decisions for stormwater management is provided in this publicly available specification The Canadian Procedure for Field Testing of Stormwater Filtration Manufactured Treatment Devices, developed by TRCA and the Standards Council of Canada that addresses both OGS and Filtration MTDs.

Testing and Verification[edit]

Several agencies across Canada require ISO 14034 Environmental Technology Verification (ETV) as a condition of technology acceptance.

(Note: when visiting the above link click on the "Other" tab on the page to view Specific Testing Protocols for OGS).

For OGS, the ISO 14034 verification process in Canada consists of two parts:

- Third party laboratory testing of MTDs in accordance with the 2023 Canadian Procedure for Laboratory Testing of Oil Grit Separators and

- Third party verification of the test in accordance with the ISO 14034 ETV standard.

The ISO 14034 verification process is currently administered by Globe Performance Solutions and Verify Global. Completed ISO 14034 verification statements for OGS are posted on the former Canadian ETV website website, here.

Note that ISO 14034 verification is a necessary, but not sufficient condition for approval agencies using the ISO/ETV process for technology acceptance. The technology must also be classified as an Oil Grit Separator (i.e. not include a filter) for the Canadian Procedure for Laboratory Testing of OGS to have been properly applied. This ETV Bulletin helps to provide clarification on this requirement: See table below for a list of current ISO 14034 verified OGS MTDs.

| Verification Year (Initial) | Technology Name | Company Name | Verification Statements |

|---|---|---|---|

| 2023 | StormSettler® Oil Grit Separator | STORMTRAP, LLC. | Verification Statement |

| 2022 | RWM-DM-1200 & DM-1200-OS Stormwater Systems | Rainwater Management LTD. | Verification Statement |

| 2021 | HydroDome® Oil-Grit Separator | HydroWorks, LLC | Verification Statement |

| 2019 | Hydro International Downstream Defender® OGS | Hydro International | Verification Statement |

| 2019 | SciCLONE™ Hydrodynamic Separator | Bio Clean Environmental Inc. (A Forterra Company) | Verification Statement |

| 2018 | Hydro International First Defense® OGS | Hydro International | Verification Statement |

| 2018 | Hydroworks® HydroStorm (HS) OGS | HydroWorks, LLC | Verification Statement |

| 2017 | Stormceptor® EF and EFO Oil-Grit Separators | Imbrium Systems, Inc., | Verification Statement |

| 2017 | CDS Hydrodynamic Separator® | CONTECH Engineered Solutions LLC | Verification Statement |

| 2016 | SDD3 Oil Grit Separator® | Next Stormwater Solutions (8091200 Canada Inc.) | Verification Statement |

Performance Test Results[edit]

The Canadian Procedure for Laboratory Testing of OGS provides performance testing for the following performance measures based on a standard sediment particle size distribution with a median particle size of 75 microns:

- Sediment removal performance: Mass balance testing at a minimum of seven surface loading rates to determine the capacity of MTDs to retain suspended solids

- Sediment scour and re-suspension test: Sediment is pre-loaded into the unit and effluent concentrations are measured at a minimum of five surface loading rates to determine how well the units retain captured sediment.

- Light liquid capture and retention test: An optional test in which beads with a density similar to motor oil are pre-loaded into the unit and the number of beads in the effluent during pre-loading and testing are measured to assess the capacity of the unit to trap and retain light liquids.

As of October 2023, there were nine OGS vendors with ISO 14034 verifications (as shown in the table above), and 12 different OGS designs that have been verified.

- The list of manufacturers and test results (Sediment Scour and Light Liquid Test Results, and other relevant operational parameters) of all OGS products and other verified technologies can be downloaded here (updated as of January 2024):

- The list of manufacturers and test results (Sediment Removal rates) of all OGS products and other verified technologies can be viewed and downloaded here (updated as of January 2024):

The verified OGS technologies can be divided into two groups based on sediment removal performance results (see group 1 and 2 in the graph below).

- Group 1 includes traditional designs (n=10) with large openings and limited flow restriction. Results for these OGS types were relatively consistent at low flows and slightly more variation at high surface loading rates.

- Group 2 units with debris filters, fine meshed debris screens or coalescing plates (n=2) showed higher performance (group 2). These units force water to flow through smaller orifices, which increase the risk of clogging, leading to higher maintenance costs in the long run. Test plans for these units should include a scenario that evaluates system hydraulics and removal rates under a scenario where a portion of the small orifices are clogged. If this has not been done, it would be reasonable to apply a factor of safety to verified results to account for clogging potential over the maintenance cycle.

In general, OGS should not be installed as stand-alone units for water quality treatment. While every effort has been made to ensure that the ISO 14034 verified lab test is an accurate representation of actual performance, there remains uncertainty about how lab results translate to the field, particularly for group 2 technologies. Installing OGS only as pretreatment to other downstream practices helps to mitigate this uncertainty and risk because downstream stormwater treatment practices can be relied on to provide a second line of defense.

Graph Above: Sediment removal efficiencies for ISO 14034 verified OGS. Group 1 units (n=10) are conventional OGS with large openings.

Group 2 units (n=2) contain additional components that filter or strain flows. Sediment removal performance results were relatively consistent across

different MTD designs, with slightly more variation at higher surface loading rates

*Note: Oil Grit Separators do not achieve the 80% removal efficiency required for stand alone application in Ontario, even at very low flow rates.

Scaling[edit]

Appropriate scaling ensures that performance results from the model tested and verified through ISO 14034 ETV can be confidently applied to other model sizes for the same MTD. Buyers should ensure to ask vendors to provide sizing data and calculations to confirm that the proposed unit is scaled appropriately. Verifications conducted in 2023 or later will include information on unit scaling in the publicly available verification statement.

The scaling rules, as stated in the Canadian Procedure[2], are as follows:

"The sediment removal rate at the specified SLRs determined for the tested full scale, commercially available MTD may be applied to similar MTDs of smaller or larger size by proper scaling. Scaling the performance results of the tested MTD to other model sizes without completing additional testing is acceptable provided that:

- The maximum treatment SLR prior to the onset of bypass for the similar MTD shall be the same or less than the tested MTD;

- The claimed sediment removal efficiencies for the similar MTD are the same or lower than the tested MTD at identical SLRs; and

- The similar MTD is scaled geometrically proportional to the tested unit in all inside dimensions of length and width and a minimum of 85% proportional in depth, where the depth dimension is measured from the outlet pipe invert to the floor of the unit.

If requirements (1), (2) and (3) are not met, then a second full scale, commercially available MTD with a difference in maximum treatment SLR prior to the onset of bypass of at least 250% shall be tested to validate the alternative scaling methodology. Testing of the similar models shall follow the same sediment removal performance testing procedures described in section 5.0. The alternative scaling methodology is deemed to be valid if the sediment removal efficiencies do not differ by more than 2% for SLRs up to

200 L min-1 m-2, and 3% for SLRs greater than 200 L min-1 m-2.”

Sizing[edit]

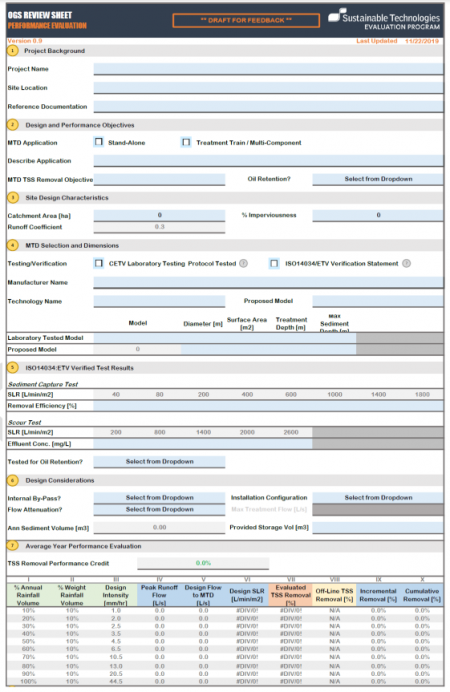

It is recommended that a standard sizing approach be used for all OGS units to ensure they are evaluated based on a consistent methodology. The attached OGS Review Calculator has been developed to facilitate application of ISO 14034 ETV test data through a standard approach applicable to all OGS MTD designs. The following methods and processes are built into the tool:

The following methods and processes are built into the tool:

- Rational Method used as a basis for flow calculations:

Where:

- Q = Peak Discharge _m3/s

- C = Runoff coefficient (unitless)<ref>

- i = Rainfall Intensity (mm/hr)

- A = Drainage Area (m2)

- Target treatment is based on capture and treatment of the average annual runoff volume for the site using ISO 14034 verified sediment removal test results for 7 surface loading rates

- Linear interpolation is used to calculate sediment removal efficiencies between the ISO/ETV tested surface loading rates

- Surface loading rates below the lowest ISO/ETV tested surface loading rate are assigned a sediment removal efficiency equal to that of the lowest tested rate

- Hourly historical rainfall data greater than 1mm for the April to October period are used to generate the rainfall intensity frequency distribution curves.

- Users may input their own rainfall intensity frequency distribution curve data for meteorological stations not provided in the tool.

Associated Documents Submitted with OGS Review Calculator[edit]

Other documents typically submitted with the OGS Review Calculator would include:

- Signed Stormwater Management (SWM) Report, engineering drawings, and specifications by the design engineer (Professional Engineer in Ontario) on behalf of their respective clients/owners

- Applicable third-party testing and verification/certification statements and documentation supporting performance claims

- Manufacturer-provided letter/documentation confirming proposed and tested MTD model details (i.e., diameter, depth, treatment depth, max storage depth, sediment storage capacity, hydraulic capacity for bypass), and compliance with sizing and scaling provisions, as per the OGS Procedure scaling provisions

- Operations and Maintenance Manual indicating the inspection and maintenance frequencies, methods of maintenance, health and safety considerations and other relevant information.

Units tested and ISO 14034 verified using the Procedure for Laboratory Testing of OGS or a modified version of the Procedure include:[edit]

ISO 14034 verified OGS vendor websites[edit]

- StormSettler® Oil Grit Separator - Developed by: StormTrap LLC.

- RWM-DM-1200 & DM-1200-OS Stormwater Systems - Developed by: Rainwater Management LTD.

- Hydro International Downstream Defender® OGS - Developed by: Hydro International.

- SciCLONE™ Hydrodynamic Separator - Developed by: Bio Clean Environmental Inc. (A Forterra Company).

- Hydro International First Defense® OGS - Developed by: Hydro International

- Hydroworks® HydroStorm (HS) OGS - Developed by HydroWorks LLC.

- Stormceptor® EF and EFO Oil-Grit Separators - Developed by: Imbrium Systems, Inc.

- CDS Hydrodynamic Separator® - Developed by: CONTECH Engineered Solutions LLC

- SDD3 Oil Grit Separator® - Developed by: Next Stormwater Solutions (8091200 Canada Inc.)

Disclaimer[edit]

In our effort to make this guide as functional as possible, we have decided to include proprietary systems and links to manufacturers websites. Inclusion of such links does not constitute endorsement by the Sustainable Technologies Evaluation Program. Lists are ordered alphabetically; link updates are welcomed using the form below.

References[edit]

- ↑ Saddoris, D.A., McIntire, K.D., Mohseni, O., and J.S. Gulliver, 2010. Hydrodynamic Separator Sediment Retention Testing – Final Report. Minnesota Department of Transportation, St. Paul, MN.

- ↑ Toronto and Region Conservation Authority, 2023. Canadian Procedure for Laboratory Testing of Oil Grit Separators: A Publicly Available Specification, Toronto, Ontario. https://sustainabletechnologies.ca/app/uploads/2023/06/SETV-OGS-PAS-2023-06-01-English-1.pdf

- ↑ City of Toronto. 2020. Proposed Manufactured Treatment Devices Guidelines. Version 0.0. Accessed: https://www.toronto.ca/services-payments/water-environment/managing-rain-melted-snow/what-the-city-is-doing-stormwater-management-projects/other-stormwater-management-projects/design-criteria-for-manufactured-treatment-devices/