Enhanced Swales: Life Cycle Costs

Overview[edit]

Enhanced swales (also referred to as Enhanced Grass Swales - EGS) are vegetated open channels designed to convey, treat and attenuate stormwater runoff. Simple grass channels or ditches have long been used for stormwater conveyance, particularly for road drainage. Enhanced swales incorporate design features such as modified geometry and check dams that improve the contaminant removal and runoff reduction functions of simple grass channel and roadside ditch designs. Where development density, topography and depth to water table permit, swales are a preferable alternative to curb and gutter and storm drains as a stormwater conveyance system. STEP has prepared life cycle costs estimates for an enhanced swale located on highly permeable native soil (Full Infiltration design), based on a 2,000 m2 road drainage area, runoff control target of 25 mm depth and 72 hour drainage period, which can be viewed below. To generate your own life cycle cost estimates customized to the development context, design criteria, and constraints applicable to your site, access the updated LID Life Cycle Costing Tool (LCCT) here.

Design Assumptions[edit]

Enhanced grass swales (EGS) are an ideal technology for sloped sites and cheaply retrofitting and improving the performance of existing grass swales. Components include: graded channel, resilient turf grass or other planting, check dams to facilitate short term ponding. Additional components include, amended soil or filter media to increase infiltration to soils below, and turf reinforcement to prevent scour. Swales can provide pretreatment for other BMPs (bioretention, soakaways, exfiltration trenches) or be designed in series with other practices as part of a treatment train.

Design and operation and maintenance program assumptions used to generate cost estimates are based on tool default values and the following STEP recommendations:

- Native soil infiltration rate for Full Infiltration Design scenario was assumed to be 20 mm/h, and a safety factor of 2.5 was applied to calculate the design infiltration rate.

- Ditch inlet catch basin structure located at furthest downgradient end, with connection to storm sewer pipe, included as the outlet.

- Operation and maintenance (O&M) cost estimates assume annual inspections, removal of trash and debris twice a year, removal of sediment from curb inlets and outlet catch basin annually, and removal of weeds twice a year. Verification inspections are included every 5 years to confirm adequate maintenance, and every 15 years to confirm adequate drainage performance through in-situ surface infiltration rate testing.

- Impervious drainage area to pervious swale footprint area of 10:1 (tool default value).

- Designed with a trapezoidal cross section with a top width of 4.75 m, bottom width of 0.75 m, and 2.5:1 side slopes (tool default values).

- Swale depth of 0.5 m, bottom length of 42.11 m and surface area at top of 200 m2.

- Longitudinal slope of 3%.

- Includes concrete curb check dams (0.3 m in height each) for every 10 m of swale length (4 in total).

- Includes a 8.4 m wide driveway and 300 mm diameter culvert crossing.

- Designed for a maximum flow velocity of 0.3 m/s.

Notes[edit]

- Design includes pretreatment through stone diaphragms at curb inlets.

- Operation and maintenance cost estimates assume rehabilitation of the swale surface is required after 25 years of operation.

- The tool calculates costs for new (greenfield) development contexts and includes costs for contractor overhead and profit, material, delivery, labour, equipment (rental, operating and operator costs), hauling and disposal.

- Land value and equipment mobilization and demobilization costs are not included, assuming BMP construction is part of overall development site construction.

- Design and Engineering cost estimates are not calculated by the tool and must be supplied by the user.

- The tool adds 10% contingency and additional overhead as default.

- All cost estimates are in Canadian dollars and represent the net present value (NPV) as the tool takes into account average annual interest and discount rates over the 25 and 50 year operating life cycle periods.

- Unit costs are based on 2018 RSMeans standard union pricing.

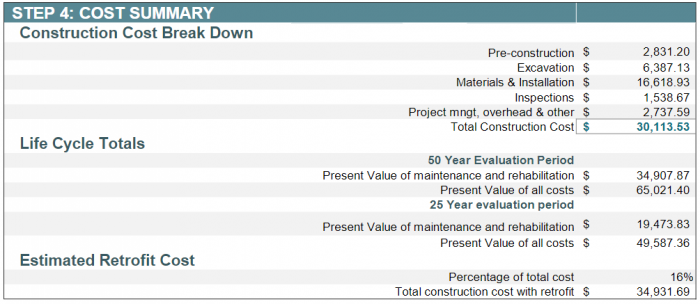

- Additional costs associated with retrofit or redevelopment contexts is assumed to be 16% of the cost estimate for new (greenfield) construction contexts.

- Retrofit construction cost estimates are included in the 'Costs Summary' section for comparison.

- Retrofit construction cost estimates are included in the 'Costs Summary' section for comparison.

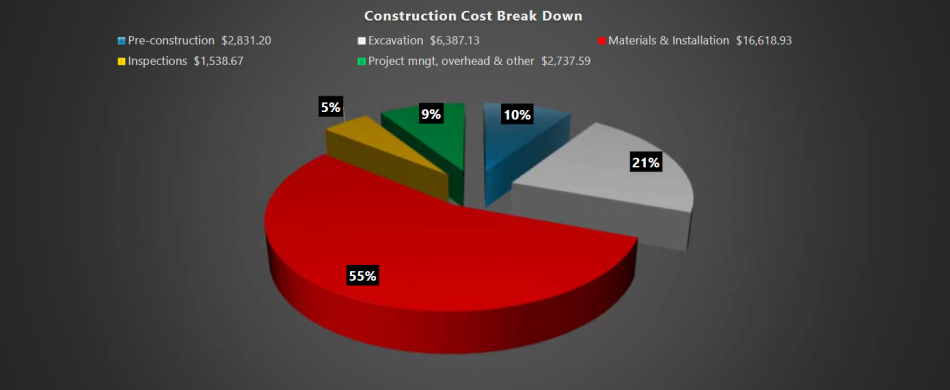

Construction Costs[edit]

Note: Please click on each image to enlarge to view associated construction cost estimates.

Above you can find a breakdown of construction costs by expense type for a 200 m2 surface area facility (I:P area ratio of 10:1):

Material & Installation expenses represent the largest portion of total construction costs (55%).

Life Cycle Costs[edit]

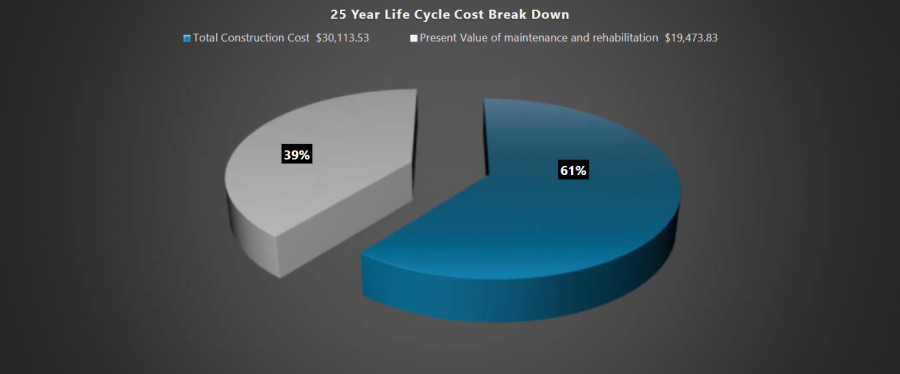

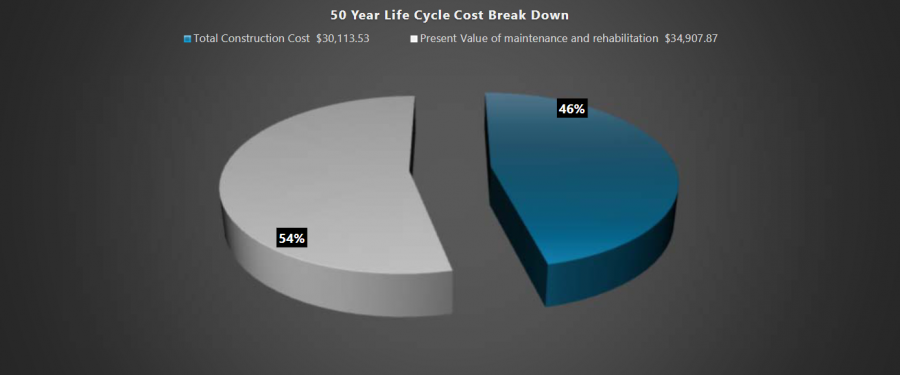

Below are capital and life cycle cost estimates for the Enhanced swales Full Infiltration configuration over 25- and 50-year time periods. The estimates of maintenance and rehabilitation (life cycle) costs represent net present values. Operation and maintenance costs are predicted to represent 39% of total life cycle costs over the 25-year evaluation period, and increase to 54% of total life cycle costs over the 50-year period, due to swale surface rehabilitation costs assumed to be required after 25 years of operation.

25-Year life cycle cost break down[edit]

Note: Click on each image to enlarge to view associated life cycle cost estimate.

50-Year life cycle cost break down[edit]

Note: Click on each image to enlarge to view associated life cycle cost estimate.

Cost Summary Tables[edit]

Total life cycle cost estimate over the 50 year evaluation period for the Enhanced swale Full Infiltration design configuration is ($65,021.40), making it one of the cheapest LID BMP options.