Difference between revisions of "Underdrains"

Jenny Hill (talk | contribs) (→Design) |

Jenny Hill (talk | contribs) |

||

| Line 9: | Line 9: | ||

*A layer of geotextile is usually then used to prevent migration of fines into the underdrain/reservoir space. | *A layer of geotextile is usually then used to prevent migration of fines into the underdrain/reservoir space. | ||

| − | === | + | ---- |

| + | ===<p></p>=== | ||

<h5>Geotextile</h5> | <h5>Geotextile</h5> | ||

{{:Geotextiles}} | {{:Geotextiles}} | ||

Revision as of 19:16, 7 July 2017

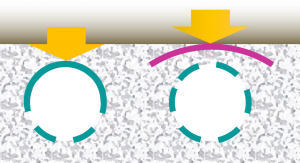

An underdrain comprises a length of perforated pipe embedded into a reservoir gravel layer. A pair of small wells are recommended to inspect and periodically flush accumulated sediment from the underdrain pipe.

- To promote infiltration the base of the gravel reservoir and the underdrain pipe should be horizontal to optimize distribution of the water within.

- Where drainage or conveyance to a downstream facility is a greater priority, the base of the reservoir and the underdrain pipe may have a gradient of up to 1-2%.

- Geotextile fabric may be used to line the reservoir space.

- A minimum of 150 mm reservoir gravel should be laid beneath the perforated pipe.

- A minimum of 300 mm reservoir gravel should be laid over the perforated pipe. An exception would be where a small bioretention installation is being made in a stormwater planter and no compaction of the reservoir material is undertaken. Otherwise this material is required to protect the pipe from the compaction processes.

- A layer of 75 - 100 mm pea gravel may then be included on top of the reservoir gravel to provide a smoother surface and reduce tearing to the geotextile.

- A layer of geotextile is usually then used to prevent migration of fines into the underdrain/reservoir space.

[edit]

Geotextile

See Clogging for notes on their application in LID structures.

Geotextiles can be used to prevent downward migration of smaller particles in to larger aggregates, and slump of heavier particles into finer underlying courses. Geotextiles are commonly used on low strength soils (CBR<4). The formation of biofilm on geotextiles has also been shown to improve water quality:

- By degrading petroleum hydrocarbons[1]

- By reducing organic pollutant and nutrient concentrations [2]

- When installing geotextiles an overlap of 150 - 300 mm should be used.

Material specifications should conform to OPSS 1860 for Class II geotextile fabrics [3]. Note when expansive clays are present, a non-infiltrating design may be necessary. If used, geotextile socks around perforated pipes should conform to ASTM D6707 with minimum water flow rate conforming to ASTM D4491 (12,263 L/min/m2 at 5 cm head).

- Fabrics should be woven monofilament or non-woven needle punched.

- Woven slit film and non-woven heat bonded fabrics should not be used, as they are prone to clogging.

In choosing a product, consider:

- The maximum forces that will be exerted on the fabric (i.e., what tensile, tear and puncture strength ratings are required?),

- The load bearing ratio of the underlying native soil (i.e. is the geotextile needed to prevent downward migration of aggregate into the native soil?),

- The texture (i.e., grain size distribution) of the overlying and underlying materials, and

- The suitable apparent opening size (AOS) for non-woven fabrics, or percent open area (POA) for woven fabrics, to maintain water flow even with sediment and microbial film build-up.

| Percent soil/filter media passing 0.075 mm (#200 sieve) | Non-woven fabric apparent opening size (AOS, mm) | Woven fabric percent open area (POA, %) | Permittivity (sec-1) |

|---|---|---|---|

| >85 | ≤ 0.3 | - | 0.1 |

| 50 - 85 | ≤ 0.3 | ≥ 4 | 0.1 |

| 15 - 50 | ≤ 0.6 | ≥ 4 | 0.2 |

| 5 - 15 | ≤ 0.6 | ≥ 4 | 0.5 |

| ≤ 5 | ≤ 0.6 | ≥ 10 | 0.5 |

Performance research[edit]

http://www.mdpi.com/2073-4441/7/4/1595/htm

Pipes

Perforated pipes are a common component of underdrains used in bioretention, permeable pavements, infiltration trenches and exfiltration systems.

Pipes should be manufactured in conformity with the latest standards by the Canadian Standards Association (CSA) or ASTM International.

- Perforated pipes should be continuously perforated, smooth interior HDPE or PVC.

- Wherever possible pipes should be ≥200 mm internal diameter to reduce potential of freezing and to facilitate push camera inspections and cleaning with jet nozzle equipment.

- Smooth interior facilitates inspection and maintenance activities; internal corrugations can cause cameras or hydrojetting apparatus to become snagged.

- A perforated pipe with many rectangular slots has better drainage characteristics than a pipe with similar open area provided by fewer circular holes [4].

- Non-perforated pipes should be used for conveyance of stormwater to and from the facility, including overflow. It is good practice to extend the solid pipe approximately 300 mm within the reservoir or practice to reduce the potential for native soil migration into the pipe.

See also: Flow through perforated pipe

Reservoir gravel

This article gives recommendations for aggregate to be used to store water for infiltration. This is usually called 'clear stone' at aggregate yards.

To see an analysis of Ontario Standard Specifications for granular materials, see OPSS aggregates.

For advice on decorative surface aggregates see Stone

Gravel used for underdrains in bioretention, infiltration trenches and chambers, and exfiltration trenches should be 20 or 50 mm, uniformly-graded, clean (maximum wash loss of 0.5%), crushed angular stone that has a porosity of 0.4[5].

The clean wash to prevent rapid accumulation of fines from the aggregate particles in the base of the reservoir. The uniform grading and the angularity are important to maintain pore throats and clear voids between particles. (i.e. achieve the porosity). Porosity and permeability are directly influenced by the size, gradation and angularity of the particles [6]. See jar test for on-site verification testing protocols.

Gravel with structural requirements should also meet the following criteria:

- Minimum durability index of 35

- Maximum abrasion of 10% for 100 revolutions and maximum of 50% for 500 revolutions

Standard specifications for the gradation of aggregates are maintained by ASTM D2940

The highest porosity is found in uniformly graded aggregate, as there are no smaller particles to occupy the inter-particle pores. [6]

Higher permeability is found in larger, angular, uniformly graded aggregate. This is due to larger pore sizes and lower tortuosity. [6]

Pea gravel

- ↑ Newman AP, Coupe SJ, Spicer GE, Lynch D, Robinson K. MAINTENANCE OF OIL-DEGRADING PERMEABLE PAVEMENTS: MICROBES, NUTRIENTS AND LONG-TERM WATER QUALITY PROVISION. https://www.icpi.org/sites/default/files/techpapers/1309.pdf. Accessed July 17, 2017.

- ↑ Paul P, Tota-Maharaj K. Laboratory Studies on Granular Filters and Their Relationship to Geotextiles for Stormwater Pollutant Reduction. Water. 2015;7(4):1595-1609. doi:10.3390/w7041595.

- ↑ ONTARIO PROVINCIAL STANDARD SPECIFICATION METRIC OPSS 1860 MATERIAL SPECIFICATION FOR GEOTEXTILES. 2012. http://www.raqsb.mto.gov.on.ca/techpubs/OPS.nsf/0/2ccb9847eb6c56738525808200628de1/$FILE/OPSS%201860%20Apr12.pdf. Accessed July 17, 2017

- ↑ Hazenberg, G., and U. S. Panu (1991), Theoretical analysis of flow rate into perforated drain tubes, Water Resour. Res., 27(7), 1411–1418, doi:10.1029/91WR00779.

- ↑ Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017

- ↑ 6.0 6.1 6.2 Judge, Aaron, "Measurement of the Hydraulic Conductivity of Gravels Using a Laboratory Permeameter and Silty Sands Using Field Testing with Observation Wells" (2013). Dissertations. 746. http://scholarworks.umass.edu/open_access_dissertations/746