Difference between revisions of "Sand"

Jump to navigation

Jump to search

Jenny Hill (talk | contribs) m |

Jenny Hill (talk | contribs) m |

||

| Line 15: | Line 15: | ||

|9.5 mm||100 | |9.5 mm||100 | ||

|- | |- | ||

| − | |4.75 mm (No.4)||95-100 | + | |4.75 mm (No.4)||95 - 100 |

|- | |- | ||

| − | |2.36 mm (No.8)||80-100 | + | |2.36 mm (No.8)||80 - 100 |

|- | |- | ||

| − | |1.18 mm (No.16)||50-85 | + | |1.18 mm (No.16)||50 - 85 |

|- | |- | ||

| − | |0.60 mm (No.30)||25-50 | + | |0.60 mm (No.30)||25 - 50 |

|- | |- | ||

| − | |0.30 mm (No.50)||5-30 | + | |0.30 mm (No.50)||5 - 30 |

|- | |- | ||

| − | |0.15 mm (No.100)||0-10 | + | |0.15 mm (No.100)||0 - 10 |

|- | |- | ||

|0.075 mm (No.200)||≤ 3 | |0.075 mm (No.200)||≤ 3 | ||

Revision as of 02:50, 8 March 2018

- Coarse sand for LID construction shall be washed clean and free free of toxic materials.

- The pH of the sand shall be ≤ 7.0.

- Manufactured sand from limestone or dolostone parent material is not acceptable.

- Sand manufactured from crushed recycled glass is available locally, and is a viable alternative.

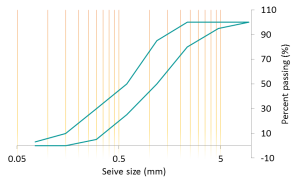

- The coarse sand shall have a fineness modulus index between 2.8 and 3.1 according to ASTM C33/C33M, or otherwise meet the gradation below.

| Sieve | Percent passing |

|---|---|

| 9.5 mm | 100 |

| 4.75 mm (No.4) | 95 - 100 |

| 2.36 mm (No.8) | 80 - 100 |

| 1.18 mm (No.16) | 50 - 85 |

| 0.60 mm (No.30) | 25 - 50 |

| 0.30 mm (No.50) | 5 - 30 |

| 0.15 mm (No.100) | 0 - 10 |

| 0.075 mm (No.200) | ≤ 3 |