Difference between revisions of "Wells"

Dean Young (talk | contribs) |

Dean Young (talk | contribs) |

||

| Line 81: | Line 81: | ||

! Notes | ! Notes | ||

|- | |- | ||

| − | | | + | |Pipe||Should consist of 100 to 150 mm diameter solid and perforated pipe sections joined together by threading or straight couplings. Perforated pipe section should consist of well screen pipe or smooth interior walled, rigid HDPE or PVC pipe with slot perforations along the full length. |

|- | |- | ||

| − | | | + | |Geotextile sock||The perforated or well screen section of the well pipe should be wrapped with a geotextile filter fabric sock to prevent sediment from accumulating in the well over time. |

|- | |- | ||

| − | | | + | |Bottom cap||The bottom of the well should be sealed with a cap to provide a small (e.g., 100 mm deep) reservoir of water to keep the water level sensor wet during dry weather. |

|- | |- | ||

| − | | | + | |Length||Shallow wells should extend into the filter media by a minimum of 150 mm. Deep wells should extend into the native soil below the facility by a minimum 150 mm. If the underdrain perforated pipe is installed in a shallow trench below the bottom of the facility, the well should extend 150 mm below the invert of the perforated pipe. Top elevation should be above the surface overflow outlet elevation or maximum ponding depth to prevent surface water from entering the well. |

|- | |- | ||

| − | | | + | |Top cap or monument||The well top should be finished with a lockable cap or standard monitoring well casing and monument to protect, secure and provide access to it. |

|- | |- | ||

| − | | | + | |Well casing|| For deep wells, the well casing should be sealed at the surface to prevent surface water from flowing along the sides of the well and affecting internal storage reservoir water level readings. Bentonite clay is often used for this purpose. |

| − | |||

| − | |||

|} | |} | ||

Revision as of 18:10, 16 June 2022

This article gives tips on the design and installation of monitoring wells into LID practices. It does not address the much deeper wells used to monitor groundwater levels. Monitoring wells are frequently installed on infiltrating systems such as bioretention, bioswales, infiltration trenches and hybrids thereof. The two questions most frequently addressed are:

- How quickly is surface ponding being infiltrated beneath the surface?

- How quickly is the facility draining through exfiltration to native soils and/or through an underdrain?

Shallow wells[edit]

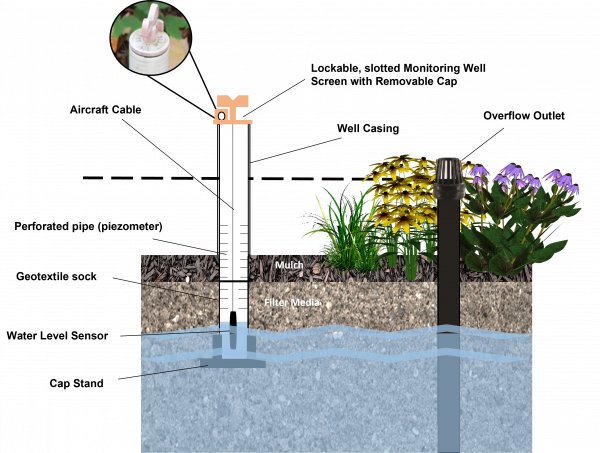

To measure the depth of ponding on the filter media bed surface, and rate at which the ponded water drains, install a shallow well with a water level logger:

- Use a section of perforated pipe or well screen with a geotextile sock around the perforated section that will allow ponded water to enter the well while preventing sediment from accumulating within it.

- Locate the well in the deepest portion of the surface ponding area or where ponding most frequently occurs.

- Measure the depth of the water level sensor in the well, relative to the filter media surface to translate sensor readings into surface ponding depth measurements.

- Ensure there is a solid cap on the bottom of the well to provide a small water reservoir (e.g., 100 mm deep) to keep the water level sensor submerged during dry conditions. This practice also helps with checking calibration of the sensor.

Deep wells[edit]

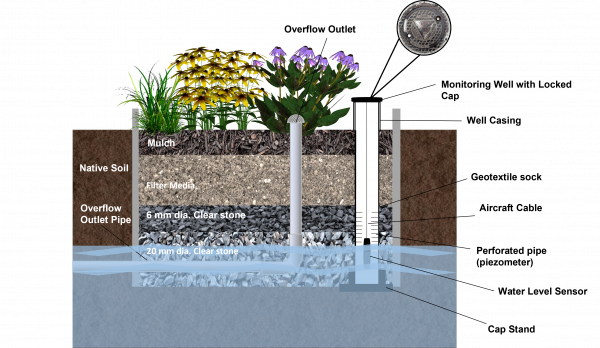

Many types of LID practices are designed to retain water within an internal water storage reservoir or layer (e.g. full and partial infiltration [[Bioretention|bioretention], stormwater tree trench and [permeable pavements|permeable pavement]] designs, infiltration trenches and chambers, and exfiltration trenches). To facilitate measurement of water level in the internal water storage reservoir or layer and periodically evaluate drainage performance over the operating life cycle of the facility, include a monitoring well located in the lowest elevation portion of the practice or system:

- Include monitoring wells in design drawings and details and install at an appropriate time during construction, or as part of repair work for facilities in need of rehabilitation.

- Ensure the perforated section of the well is located within the internal water storage reservoir or layer only, and that it extends to the bottom elevation of the practice at a minimum.

- Design and install the well so that surface water will not affect water level readings.

- A standard monitoring well casing and cap or monument to protect, secure and provide access to the well should also be included.

- Ensure there is a solid cap on the bottom of the well to provide a small water reservoir (e.g., 100 mm deep) to keep the water level sensor submerged during dry conditions. This practice also helps with checking calibration of the sensor.

- Where possible, wells should be located in areas with little or no vehicular traffic for ease of access.

Monitoring Well Specifications[edit]

| Feature | Notes |

|---|---|

| Pipe | Should consist of 100 to 150 mm diameter solid and perforated pipe sections joined together by threading or straight couplings. Perforated pipe section should consist of well screen pipe or smooth interior walled, rigid HDPE or PVC pipe with slot perforations along the full length. |

| Geotextile sock | The perforated or well screen section of the well pipe should be wrapped with a geotextile filter fabric sock to prevent sediment from accumulating in the well over time. |

| Bottom cap | The bottom of the well should be sealed with a cap to provide a small (e.g., 100 mm deep) reservoir of water to keep the water level sensor wet during dry weather. |

| Length | Shallow wells should extend into the filter media by a minimum of 150 mm. Deep wells should extend into the native soil below the facility by a minimum 150 mm. If the underdrain perforated pipe is installed in a shallow trench below the bottom of the facility, the well should extend 150 mm below the invert of the perforated pipe. Top elevation should be above the surface overflow outlet elevation or maximum ponding depth to prevent surface water from entering the well. |

| Top cap or monument | The well top should be finished with a lockable cap or standard monitoring well casing and monument to protect, secure and provide access to it. |

| Well casing | For deep wells, the well casing should be sealed at the surface to prevent surface water from flowing along the sides of the well and affecting internal storage reservoir water level readings. Bentonite clay is often used for this purpose. |