Difference between revisions of "Reservoir aggregate"

Jenny Hill (talk | contribs) m |

Jenny Hill (talk | contribs) m |

||

| Line 1: | Line 1: | ||

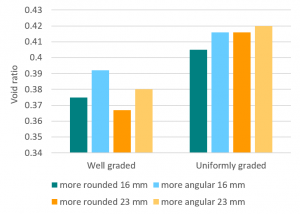

[[File:Particle void ratio.png|thumb|The highest void ratio is found in uniformly graded aggregate, as there are no smaller particles to occupy the inter-particle pores. <ref name = Judge/>]] | [[File:Particle void ratio.png|thumb|The highest void ratio is found in uniformly graded aggregate, as there are no smaller particles to occupy the inter-particle pores. <ref name = Judge/>]] | ||

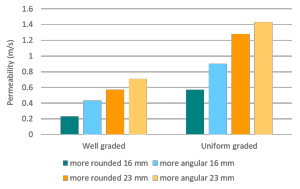

| − | [[File:Particle permeability.png|thumb|Higher permeability is found in larger, angular, uniformly graded aggregate. This is due to larger pore sizes and lower tortuosity. <ref name = Judge/> | + | [[File:Particle permeability.png|thumb|Higher permeability is found in larger, angular, uniformly graded aggregate. This is due to larger pore sizes and lower tortuosity. <ref name = Judge/>]] |

| − | + | This article gives recommendations for aggregate to be used to store water for infiltration. This is usually called 'Clear stone' at aggregate yards. To see an analysis of Ontario Standard Specifications for granular materials, see [[OPS Aggregates]]. For advice on decorative surface aggregates see [[Stone]] | |

| − | This article gives recommendations for aggregate to be used to store water for infiltration. This is usually called 'Clear stone' at aggregate yards. | ||

| − | |||

| − | To see an analysis of Ontario Standard Specifications for granular materials, see [[OPS Aggregates]]. | ||

Gravel used for [[underdrains]] in [[bioretention]], [[infiltration trenches]] and [[infiltration chambers|chambers]], and [[exfiltration trenches]] should be 20 OR 50 mm, uniformly-graded, clean (maximum wash loss of 0.5%), crushed angular stone that has a void ratio of 0.4<ref>Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017 </ref>. | Gravel used for [[underdrains]] in [[bioretention]], [[infiltration trenches]] and [[infiltration chambers|chambers]], and [[exfiltration trenches]] should be 20 OR 50 mm, uniformly-graded, clean (maximum wash loss of 0.5%), crushed angular stone that has a void ratio of 0.4<ref>Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017 </ref>. | ||

Revision as of 19:22, 12 June 2018

This article gives recommendations for aggregate to be used to store water for infiltration. This is usually called 'Clear stone' at aggregate yards. To see an analysis of Ontario Standard Specifications for granular materials, see OPS Aggregates. For advice on decorative surface aggregates see Stone

Gravel used for underdrains in bioretention, infiltration trenches and chambers, and exfiltration trenches should be 20 OR 50 mm, uniformly-graded, clean (maximum wash loss of 0.5%), crushed angular stone that has a void ratio of 0.4[2].

The clean wash to prevent rapid accumulation of fines from the aggregate particles in the base of the reservoir. The uniform grading and the angularity are important to maintain pore throats and clear voids between particles. (i.e. achieve the void ratio). Porosity and permeability are directly influenced by the size, gradation and angularity of the particles [1]. See jar test for on-site verification testing protocols.

Gravel with structural requirements should also meet the following criteria:

- Minimum durability index of 35

- Maximum abrasion of 10% for 100 revolutions and maximum of 50% for 500 revolutions

Standard specifications for the gradation of aggregates are maintained by ASTM D2940

- ↑ 1.0 1.1 1.2 Judge, Aaron, "Measurement of the Hydraulic Conductivity of Gravels Using a Laboratory Permeameter and Silty Sands Using Field Testing with Observation Wells" (2013). Dissertations. 746. http://scholarworks.umass.edu/open_access_dissertations/746

- ↑ Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017