Difference between revisions of "Pipes"

Jump to navigation

Jump to search

Jenny Hill (talk | contribs) |

|||

| (24 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

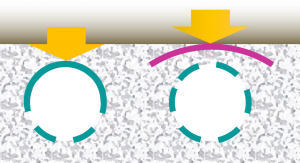

| − | + | [[File:Perforations.png|thumb|Pipes are available with perforations on just one side, these should be situated on the lower half of the pipe. Pipes with 360° perforations should have a strip of geotextile or membrane placed over the pipe to reduce the migration of fines from overlying media.]] | |

| − | *Perforated pipes should be continuously perforated, smooth interior HDPE | + | Perforated pipes are a common component of [[underdrains]] used in [[bioretention]], [[permeable pavements]], [[infiltration trenches]] and [[exfiltration trenches| exfiltration systems]]. |

| − | ** | + | |

| − | ** | + | Pipes should be manufactured in conformity with the latest standards by the Canadian Standards Association (CSA) or ASTM International. |

| − | * | + | *Perforated pipes should be continuously perforated, smooth interior HDPE or PVC. |

| − | + | **Wherever possible pipes should be ≥200 mm internal diameter to reduce potential of freezing and to facilitate push camera inspections and cleaning with jet nozzle equipment. | |

| − | + | **Smooth interior facilitates inspection and maintenance activities; internal corrugations can cause cameras or hydrojetting apparatus to become snagged. | |

| − | + | **A perforated pipe with many rectangular slots has better drainage characteristics than a pipe with similar open area provided by fewer circular holes <ref>Hazenberg, G., and U. S. Panu (1991), Theoretical analysis of flow rate into perforated drain tubes, Water Resour. Res., 27(7), 1411–1418, doi:10.1029/91WR00779.</ref>. | |

| − | + | *Non-perforated pipes should be used for conveyance of stormwater to and from the facility, including [[overflow]]. It is good practice to extend the solid pipe approximately 300 mm within the reservoir or practice to reduce the potential for native soil migration into the pipe. | |

| − | *Non-perforated pipes should be used for conveyance to and | + | |

| − | + | <gallery mode="packed" widths=200px heights=200px> | |

| − | + | Perforated Pipe 550x550.jpg|Pipe with slotted perforations | |

| − | + | Pipe with connector.jpg|Perforated pipes awaiting installation, note the 45 degree couplings used to facilitate push camera inspection and jet nozzle cleaning. | |

| − | <gallery mode="packed" widths= | ||

| − | Perforated Pipe 550x550.jpg| Pipe | ||

</gallery> | </gallery> | ||

| − | + | See also: [[Flow through perforated pipe]] | |

| − | + | ---- | |

[[Category:Materials]] | [[Category:Materials]] | ||

Latest revision as of 18:03, 6 August 2020

Perforated pipes are a common component of underdrains used in bioretention, permeable pavements, infiltration trenches and exfiltration systems.

Pipes should be manufactured in conformity with the latest standards by the Canadian Standards Association (CSA) or ASTM International.

- Perforated pipes should be continuously perforated, smooth interior HDPE or PVC.

- Wherever possible pipes should be ≥200 mm internal diameter to reduce potential of freezing and to facilitate push camera inspections and cleaning with jet nozzle equipment.

- Smooth interior facilitates inspection and maintenance activities; internal corrugations can cause cameras or hydrojetting apparatus to become snagged.

- A perforated pipe with many rectangular slots has better drainage characteristics than a pipe with similar open area provided by fewer circular holes [1].

- Non-perforated pipes should be used for conveyance of stormwater to and from the facility, including overflow. It is good practice to extend the solid pipe approximately 300 mm within the reservoir or practice to reduce the potential for native soil migration into the pipe.

See also: Flow through perforated pipe

- ↑ Hazenberg, G., and U. S. Panu (1991), Theoretical analysis of flow rate into perforated drain tubes, Water Resour. Res., 27(7), 1411–1418, doi:10.1029/91WR00779.