Infiltration trenches

This article is about underground systems which distribute concentrated flow along a level, linear facility to promote infiltration to native soils.

See exfiltration trenches for guidance on infiltration trench systems integrated with conventional storm sewers and manholes that provide both infiltration and conveyance functions.

Overview[edit]

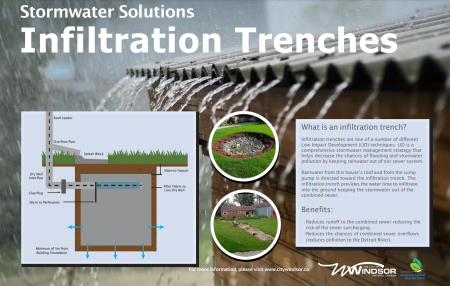

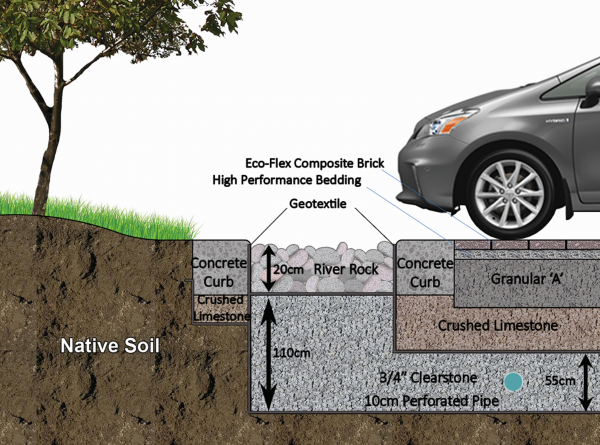

Infiltration trenches are underground, linear, rectangular or trapezoidal excavations with level or gently sloping bottom grade, geotextile filter fabric on sidewalls and top and filled with clean, crushed angular stone or other void-forming structures. They are well suited to sites where available space for infiltration is limited to strips of land between buildings or properties, or along road rights-of-way. They can also be referred to as infiltration galleries. See Perforated Pipe Systems fact sheet for guidance on infiltration trench systems integrated with conventional storm sewers that provide both infiltration and conveyance functions.

Infiltration trenches are an ideal technology for:

- Installing below any type of surface or landscape

- Balancing the requirements to infiltrate excess stormwater whilst conveying excess

Take a look at the downloadable Soakaways, Infiltration Trenches & Chambers Factsheet below for a .pdf overview of this LID Best Management Practice:

The fundamental components of an infiltration trench are:

- Water storage reservoir, filled with coarse aggregate, possibly void-forming structures to minimize depth and conserve aggregate, and organic material derived from untreated wood (aids in dissolved nitrogen removal);

- Perforated pipes to deliver water to the trench and convey excess flow to a downstream storm sewer or other BMP; and

- Geotextile to maintain separation between the storage reservoir and surrounding native soil.

Planning considerations[edit]

As shown in the illustration above a surface inlet to an infiltration trench may simply be a channel of decorative stone supported by a geotextile. So that at grade it may be indistinguishable from a gravel diaphragm. In function though, the decorative surface course of the infiltration trench needs to remain free-draining down into the trench, whereas the gravel diaphragm is designed to spill over onto adjacent land, leaving sediment behind in the gravel or stone channel.

All types of modular infiltration systems require a bedding of angular clear stone to permit infiltration, and provide a foundation for the installation:

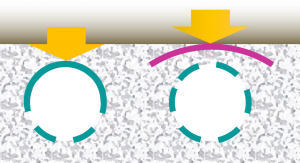

- Plastic chambers usually have a parabolic shape to support the load above. The spaces between rows of plastic pipes or chambers are filled with clear stone to support overlying structures.

- Concrete vaults and plastic crates are often rectangular-shaped. Concrete vault systems can, in some circumstances, be employed without any additional cover. However, a minimum of 20 cm cover is recommended for most applications. Where this cover is planting soil this can support turf grass. Greater planting soil depths are required to support more deeply rooting plants like perennials and shrubs (45 to 60 cm) and trees (85 to 100 cm).

Infiltration[edit]

For information about constraints to infiltration practices, and approaches and tools for identifying and designing within them see Infiltration.

Native Soil[edit]

Infiltration trenches, chambers and soakaways can be constructed over any soil type, but hydrologic soil group (HSG) A or B soils are best for achieving water balance and erosion control objectives. Facilities should be located on portions of the site with the highest infiltration rates. Native soil infiltration rate at the proposed facility location and depth should be confirmed through in-situ measurements of hydraulic conductivity under field saturated conditions. For guidance on infiltration testing and selecting a design infiltration rate see Design infiltration rate.

Wellhead Protection[edit]

Facilities receiving road or parking lot runoff should not be located within two (2) year time-of-travel wellhead protection areas (see drinking water source protection plan).

Available Space[edit]

Recommended under parking, walkway or landscape areas and require little surface space, solely for inlets, outlets and access structures.

Site Topography[edit]

Facilities cannot be located on natural slopes greater than 15%.

Water Table[edit]

Maintaining a separation of one (1) metre between the elevations of the base of the practice and the seasonally high water table, or top of bedrock is recommended. Lesser or greater values may be considered based on groundwater mounding analysis. See Groundwater for further guidance and spreadsheet tool.

Pollution Hot Spot Runoff[edit]

To protect groundwater from possible contamination, runoff from pollution hot spots should not be treated by infiltration trenches, chambers or soakaways.

Proximity to Underground Utilities[edit]

Designers should consult local utility design guidance for the horizontal and vertical clearances required between storm drains.

Karst[edit]

Infiltration trenches, chambers and soakaways are not suitable in areas of known or implied karst topography.

Setback from Buildings[edit]

Facilities should be setback a minimum of four (4) metres from building foundations.

For a table summarizing information on planning considerations and site constraints see Site considerations.

Design[edit]

Sizing[edit]

Infiltration: Sizing and modeling

- Virginia up to 10' (3 m) deep. [2]

- Minnesota up to 12' (3.6 m) deep. [3]

- "...not normally deeper than 3 to 4 m in order to maximise the length of the flow path to the water table through the unsaturated zone." [4]

- There is a cost implication with designing deeper practices. If >2.0 m deep, trench shorings are required to support the side walls during construction.

Geometry and Site Layout[edit]

Infiltration chambers and soakaways can be designed in a variety of shapes, although facilities should have level or nearly level bottoms to spread flow evenly throughout. Typically designed with an impervious drainage area to pervious facility footprint area ratio (i.e. I:P ratio) between 5:1 on low permeability soils (HSG C & D) to 20:1 on high permeability soils (HSG A & B). Not typically deeper than 4 m.

| LID Stormwater Management Practice | Depth to high water

table or bedrock (m) |

Typical Ratio of

Impervious Drainage Area to Treatment Facility Area |

Native Soil Infiltration Rate

(mm/hr)3 |

Head | Space | Slope | Pollution Hotspots* | Set backs** |

|---|---|---|---|---|---|---|---|---|

| Soakaway,

infiltration trench or infiltration chamber |

1 | 5:1 to 20:1 | Not a constraint | 1 to 2 | 0 to 1 | < 15% | No | B, U, T, W |

*Is the LID SWM BMP practice suitable to be located in known pollution hot spots or runoff source areas where land uses or activities have the potential to generate highly contaminated runoff? This could include fueling centers, demolition zones, outdoor storage or handling areas that house hazardous materials, etc. fueling, servicing or demolition areas, outdoor storage or handling areas for hazardous materials and some heavy industry sites).

**Setback codes: B = Building foundation; U = Underground utilities; T = Trees; W = drinking water wellhead protection areas.

Inlets[edit]

Recommended to distribute inflow between multiple inlets to reduce risk of failure. May include delivery of runoff to the facility as concentrated overland or concentrated underground (i.e. pipe) flow. For concentrated overland flow:

- Catch basins or other inlet structures should be located at all sag points in the gutter grade and immediately upgrade of median breaks, crosswalks and street intersections,

- inlet types include curb openings, side inlet catch basins, trench drains, and other pre-fabricated inlet structures,

- spillways aid in turning flow 30, 45 or 90 degrees into the practice,

- if the inlet structure itself does not provide sedimentation or filtration pre-treatment, incorporate a geotextile and stone filter inlet at curb opening or spillway locations to isolate sediment, trash and debris for ease of removal, and

- provide a 50 to 100 mm drop in elevation between inlet invert and top elevation of the stone cover.

For concentrated underground flow, inlets may include plastic or concrete pipes from roof drains or catch basins, storm sewers, OGSs or outlet leader from an upstream BMP. Solid pipe transitions to perforated pipe within the storage reservoir 0.3 m from the sides. Trench plugs should be installed around solid pipes where they enter and exit the storage reservoir.

Pre-Treatment[edit]

It is important to prevent sediment, trash and debris from entering infiltration facilities because they could contribute to clogging and failure of the system. Infiltration practices may be used to treat runoff from roofs and pavements with sedimentation or filtration pre-treatment. The following pre-treatment options help facilitate maintenance and reduce risk of failure by confining sediment and debris to an accessible area, thereby reducing the potential for system clogging:

- Leaf screens are mesh screens installed either on the building eavestroughs or roof downspouts and are used to remove leaves and other large debris from roof runoff.

- Catch basin, manhole or other inlet structure sumps in combination with a shield, baffle, trap, or filter insert device, or goss trap, are used to pre-treat concentrated overland flow. They can be designed to retain both coarse and fine particulate sediments in the sump, and floatables (hydrocarbons, trash and debris). A variety of proprietary pre-treatment devices are available.

- Oil and grit (hydrodynamic) separators (OGS) are used for concentrated underground flow.

- Infiltration chambers are designed with an isolated filter row at inlets, not connected by pipes to the other chambers, that isolates the bulk of sediment and associated pollutants and is designed for ease of access by jet flushing cleaning equipment.

- Grass swales can be used to pre-treat road and parking lot runoff . Provide a 75 to 150 mm elevation drop between the inlet invert and swale surface.

- Geotextile and stone filter inlets are, square or rectangular curb openings located directly over the practice, filled with clean aggregate, covered with a layer of geotextile filter fabric and stone, graded level and installed at concentrated overland flow inlets. Elevation change of 75 to 100 mm from pavement to top of the stone cover. Stone cover may be 50 to 150 mm diameter crushed angular stone, river rock/beach stone or rip rap.

Storage Reservoir[edit]

Depth must meet both runoff storage and structural support requirements. See STEP LID Planning and Design Guide wiki page, Infiltration: Sizing and modeling, for guidance and spreadsheet tool for determining the reservoir depth and area required to store the design storm runoff volume. Should be filled with uniformly graded, washed 25 or 50 mm diameter crushed angular stone (max. wash loss of 0.5%) with a porosity of 0.4. For facilities located under load-bearing structures like pavements, aggregate should have a minimum durability index of 35, and a maximum abrasion of 10% for 100 revolutions and 50% for 500 revolutions. Include organic material derived from untreated wood (e.g. chips, mulch or shavings) to enhance nitrogen removal.

Void-forming structures[edit]

Includes chambers, vaults, crates or perforated pipes that provide large water storage volume per unit area, reduce required facility footprint area and conserve aggregate. Plastic chamber systems should be compliant with CSA B184 SERIES 11 (R2015) or ASTM F2418-16A. Maximum allowable load for plastic chambers must be determined in accordance with ASTM F2787-13. Concrete vault systems should be compliant with CSA A23.3-14 and CSA A23.1-09/A23.2-09 (R2014) or ASTM C858-10e1. See manufacturer for product specific specifications regarding maximum load, minimum cover depth and porosity or water storage per unit area.

Geotextile[edit]

Storage reservoirs should be lined on the sides and top with geotextile filter fabric to maintain separation from the native soil. Geotextile on the base is optional but may be prone to blinding and eventual clogging. Material specifications should conform to Ontario Provincial Standard Specification (OPSS) 1860 for Class II geotextile fabrics. Should be woven monofilament or non-woven needle punched, or woven monofilament with a minimum overlap of 300 mm. Woven slit film and non-woven heat bonded fabrics should not be used as they are prone to clogging. Specification of geotextile fabrics should consider the apparent opening size (AOS) for non-woven fabrics, or percent open area (POA) for woven fabrics, to maintain water flow even with sediment and microbial film build-up. Other factors that need consideration include maximum forces to be exerted on the fabric, and the load bearing ratio, texture (i.e., grain size distribution) and permeability of the native soil in which they will be installed. Geotextile socks around perforated pipes should conform to ASTM D6707 with minimum water flow rate conforming to ASTM D4491 (12,263 L/min/m2 at 5 cm head).

Perforated pipes[edit]

Continuously perforated, smooth interior HDPE or PVC drainage pipe, ≥200 mm interior diameter where possible to reduce risk of freezing and facilitate push camera inspection and cleaning with jet nozzle equipment. Including geotextile socks around perforated pipes is optional. May include an orifice plate or valve flow restrictor to provide erosion control and optimize infiltration.

Conveyance and Overflow[edit]

Typically designed to be offline where a flow control structure or inlet allows only the design storm runoff volume to enter the facility. Excess flows are conveyed to a downstream storm sewer or other BMP by a flow-splitting manhole (i.e. flow through riser) containing a weir and overflow outlet pipe, or by by-passing the curb opening and flowing into a down-gradient catch basin. Overflow structures must be sized to safely convey large event flows. The overflow outlet should be below the maximum frost penetration depth (i.e. frost line) to function year round.

Monitoring Wells[edit]

Recommended for monitoring drainage time between storms. Monitoring wells should be a vertical standpipe consisting of an anchored 100 to 150 mm diameter pipe with perforations along the length within the reservoir, installed to the bottom of the facility, with a lockable cap. Flow-splitting manholes may also be used for drainage time monitoring.

Simplified cross section of a standard monitoring well.[5]

Access Structures[edit]

Manholes or maintenance hatches connected to infiltration chambers, or standpipe inspection ports connected to infiltration trench or soakaway perforated pipe that provide access for inspection and maintenance. Should be installed at inlets and outlets at a minimum. Couplings used for standpipe connections should be 45° to facilitate pipe access by push camera and jet nozzle cleaning equipment.

Ability to Meet Stormwater Criteria[edit]

| BMP Type | Water Balance | Water Quality | Erosion Control |

|---|---|---|---|

| Infiltration Trenches,

Chambers and Soakaways |

Yes | Yes | Yes |

Materials[edit]

Aggregate[edit]

This article gives recommendations for aggregate to be used to store water for infiltration. This is usually called 'clear stone' at aggregate yards.

To see an analysis of Ontario Standard Specifications for granular materials, see OPSS aggregates.

For advice on decorative surface aggregates see Stone

Gravel used for underdrains in bioretention, infiltration trenches and chambers, and exfiltration trenches should be 20 or 50 mm, uniformly-graded, clean (maximum wash loss of 0.5%), crushed angular stone that has a porosity of 0.4[6].

The clean wash to prevent rapid accumulation of fines from the aggregate particles in the base of the reservoir. The uniform grading and the angularity are important to maintain pore throats and clear voids between particles. (i.e. achieve the porosity). Porosity and permeability are directly influenced by the size, gradation and angularity of the particles [7]. See jar test for on-site verification testing protocols.

Gravel with structural requirements should also meet the following criteria:

- Minimum durability index of 35

- Maximum abrasion of 10% for 100 revolutions and maximum of 50% for 500 revolutions

Standard specifications for the gradation of aggregates are maintained by ASTM D2940

The highest porosity is found in uniformly graded aggregate, as there are no smaller particles to occupy the inter-particle pores. [7]

Higher permeability is found in larger, angular, uniformly graded aggregate. This is due to larger pore sizes and lower tortuosity. [7]

Other[edit]

Perforated Pipe[edit]

Perforated pipes are a common component of underdrains used in bioretention, permeable pavements, infiltration trenches and exfiltration systems.

Pipes should be manufactured in conformity with the latest standards by the Canadian Standards Association (CSA) or ASTM International.

- Perforated pipes should be continuously perforated, smooth interior HDPE or PVC.

- Wherever possible pipes should be ≥200 mm internal diameter to reduce potential of freezing and to facilitate push camera inspections and cleaning with jet nozzle equipment.

- Smooth interior facilitates inspection and maintenance activities; internal corrugations can cause cameras or hydrojetting apparatus to become snagged.

- A perforated pipe with many rectangular slots has better drainage characteristics than a pipe with similar open area provided by fewer circular holes [8].

- Non-perforated pipes should be used for conveyance of stormwater to and from the facility, including overflow. It is good practice to extend the solid pipe approximately 300 mm within the reservoir or practice to reduce the potential for native soil migration into the pipe.

See also: Flow through perforated pipe

Construction[edit]

Oil Disturbance and Compaction[edit]

Before site work begins, locations of facilities should be clearly marked. Ideally, infiltration practice locations should remain outside the limit of disturbance until construction of the facility begins to prevent soil compaction by heavy equipment.

Excavation[edit]

If >2.0 m in depth, trench shorings will be required to support the sidewalls. Use a toothed bucket to excavate and roughen the excavation bottom and sides prior to backfilling.

Erosion and Sediment Control[edit]

Infiltration practice locations should not be used as sediment basins during construction. To prevent sediment from clogging, erosion and sediment controls should remain in place and runoff should be diverted from the infiltration facility until the contributing drainage area is fully stabilized and sediment removal from catch basins, pre-treatment devices and maintenance hole sumps has been completed.

Operation and Maintenance[edit]

Infiltration trenches, chambers and soakaways will continue to function during winter months if the overflow outlet is located below the local maximum frost penetration depth (i.e. frost line).

Routine inspection and maintenance consists of checking and cleaning trash, debris and sediment from pre-treatment devices, inlets and outlets twice a year in the spring and/or late fall, or when pre-treatment device sump is half full. Use hydro-vac truck to remove sediment from catch basin sumps, OGS and isolated chamber row filter pre-treatment devices. To clean isolated chamber row filters use a vacuum truck equipped with rear-facing jet nozzle for cleaning large diameter pipes or culverts.

Monitoring of storage reservoir water level during and after natural or simulated storm events using the monitoring well should be performed periodically to verify the facility drains within the required drainage time (typically 72 hours). Should be performed as part of inspections following construction or major rehabilitation prior to assumption, and every 15 years at a minimum, to track drainage performance over time and determine when replacement is needed.

See also *Construction

Gallery[edit]

View of infiltration trench in U.S. Photo credit: Moreau1

- ↑ The City of Windsor. Stormwater Solutions: Infiltration Trenches. https://www.citywindsor.ca/residents/environment/climate-change-adaptation/climate-resilient-home/Documents/Infiltration%20Trench.pdf. Updated 2021. Accessed 30 August, 2021

- ↑ Viriginia Department of Transport. (2010). VDOT BMP Design Manual of Practice. Retrieved March 15, 2018, from http://www.virginiadot.org/business/resources/LocDes/BMP_Design-Manual/Chapter_8_Infiltration_Trench.pdf

- ↑ Design criteria for Infiltration trench. (2016, September 21). Minnesota Stormwater Manual, . Retrieved 13:25, April 4, 2018 from https://stormwater.pca.state.mn.us/index.php?title=Design_criteria_for_Infiltration_trench&oldid=28702.

- ↑ Design of soakaways (2015) www.tiipublications.ie/library/DN-DNG-03072-01.pdf

- ↑ Hawaii State Department of Health. TGM for the Implementation of the Hawai'i State Contingency Plan. Subsection 6.2. MONITORING WELL INSTALLATION AND ABANDONMENT. http://hawaiidoh.org/tgm-content/0602a.aspx?f=T. Published (n.d.). Retrieved August 27, 2021.

- ↑ Porosity of Structural Backfill, Tech Sheet #1, Stormtech, Nov 2012, http://www.stormtech.com/download_files/pdf/techsheet1.pdf accessed 16 October 2017

- ↑ 7.0 7.1 7.2 Judge, Aaron, "Measurement of the Hydraulic Conductivity of Gravels Using a Laboratory Permeameter and Silty Sands Using Field Testing with Observation Wells" (2013). Dissertations. 746. http://scholarworks.umass.edu/open_access_dissertations/746

- ↑ Hazenberg, G., and U. S. Panu (1991), Theoretical analysis of flow rate into perforated drain tubes, Water Resour. Res., 27(7), 1411–1418, doi:10.1029/91WR00779.