Enhanced swales

This article is about installations designed to capture and convey surface runoff along a vegetated channel, whilst also promoting infiltration.

For underground conveyance which promotes infiltration, see Exfiltration trenches.

For conveyance along planted channels, on both surface and underground, see Bioswales.

Overview[edit]

Enhanced swales are an ideal technology for:

- Sloped sites,

- Cheaply retrofitting and improving the performance of existing grass swales.

The fundamental components of an enhanced grassed swale are:

- Graded channel

- Resilient turf grass

- Check dams, to facilitate short term ponding

Additional components may include:

- Amended soil, to of filter media increase infiltration to soils below

- Turf reinforcement, to prevent scour

Planning considerations[edit]

When planning a new site, all swales and overground flow paths should be fitted perpendicular to existing contours. See Natural drainage and Existing hydrology.

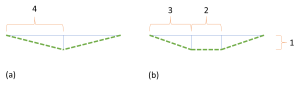

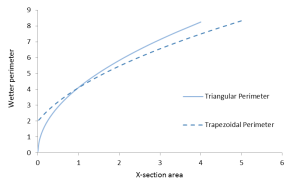

Best cross sections[edit]

Enhanced swales aim to both reduce the flow rate and retain a portion of the conveyed water. For these purposes the best x-section is that which maximizes the wetted perimeter for a given area. For a given width and depth, the difference between a triangular and trapzoidal section is small. As shown in the diagrams, under low flow conditions the trapezoidal has greater wetted perimeter, and at higher flows the triangular profile does.

Safety[edit]

As shallow grassed swales are a common roadside construction, the Ministry of Transport has created their own guide to maximum flow depth and freeboard[1][2]. Their advice has been prepared specifically for high risk environments and those stringent constraints should not be applied to all circumstances. In many urban environments the principle of applying check dams to enhance all surface BMPS can be safely used to encourage ponding and subsequent infiltration for a day or two.

Design[edit]

All swales should be designed to meet the following criteria:

- Minimum residence time of 5 minutes.

- Maximum flow velocity 0.3 m/s

- Bottom width between 0.6 - 2.4 m

- Minimum length 30 m

Maximum depth of flow

- 50% height of grass for regularly mown swales, to maximum of 75 mm.

- 33% height of vegetation for infrequently mown swales.

Modeling[edit]

It is recommended that grass and enhanced grass swales be modelled using the 'Swale' element in the TTT. A 'swale' has to connect two existing elements within the TTT Bioswales or dry swales, which have amended filter media, should be modelled as bioretention cells. The alternative is to use the 'enhanced swale' within the LID toolbox, but this incorporates fewer design parameters (and doesn't account for infiltration).

| General Info | |

|---|---|

| Upstream Node | Name of node on the inlet end of the swale (higher elevation) |

| Downstream Node | Name of node on the outlet end of the swale (lower elevation) |

| Manning's Roughness | Lower numbers indicate less surface obstruction and result in faster flow. Suggested range for mown grass (dependent on density) 0.03 – 0.06 [3] |

| Upstream Invert (m) | Depth of swale invert above node invert at inlet end of the swale |

| Downstream Invert (m) | Depth or elevation of the swale invert above the node invert at the outlet end of the swale |

| Cross section | |

| Maximum Depth (m) | Depth of the swale |

| Bottom Width (m) | Bottom width of the trapezoidal swale For a triangular channel, enter 0 |

| Left Side Slope (m/m) | Left side slope (run/rise). Suggested value of 3 or 4 if design permits. |

| Right Side Slope (m/m) | Right side slope (run/rise). Suggested value of 3 or 4 if design permits. |

| Seepage (mm/hour) | Infiltration rate of native (or amended) soil |

| Surface | |

|---|---|

| Berm height (mm) | This is the height of the curb which constrains the overland sheet flow of water. Where the bottom of the slope discharges directly into another LID facility without impedance, the value is 0. |

| Surface roughness (Manning’s n) | Lower numbers indicate less surface obstruction and result in faster flow. Suggested range for mown grass (dependent on density) 0.03 – 0.06 [3] |

| Surface slope (%) | If the slope > 3%, use Check dams to create temporary ponding, increase infiltration, and slow flow to reduce erosion. |

| Swale side slopes (run/rise) | Suggested value of 3 or 4 if design permits. |

Materials[edit]

Resilient turf grasses are particularly useful in the design of vegetated filter strips, dry ponds and enhanced grass swales. The Ministry of Transportation have standardized a number of grass mixes[4]. The 'Salt Tolerant Mix' is of particular value for low impact development applications alongside asphalt roadways and paved walkways.

| Common name | Scientific name | Proportion |

|---|---|---|

| Tall Fescue | Festuca arundinacea | 25 % |

| Fults Alkali Grass | Puccinellia distans | 20 % |

| Creeping Red Fescue | Festuca rubra | 25 % |

| Perennial ryegrass | Lolium perrenne | 20 % |

| Hard Fescue | Festuca trachyphylla | 10 % |

For advice on aggregates used in underdrains, see Reservoir aggregate.

Stone or gravel can serve as a low maintenance decorative feature, but it may also serve many practical functions on the surface of an LID practice.

Stone for erosion control[edit]

Aggregates used to line swales or otherwise dissipate energy (e.g. in forebays) should have high angularity to increase the permissible shear stress applied by the flow of water. [5] However, in some surface landscaped applications there may be a desire to use a rounded aggregate such as 'river rock' for aesthetic reasons. Rounded stones should be of sufficient size to resist being moved by the flow of water. Typical stone for this purpose ranges between 50 mm and 250 mm in diameter. The larger the stone, the more energy dissipation.

- Stone beds should be twice as thick as the largest stone's diameter.

- If the stone bed is underlain by a drainage geotextile, annual inspection and possible replacement should be performed as there is a potential for clogging of this layer to occur.

Stone lining the ponding zone of this rain garden. Image credit California Native Plant Society

Coarse angular stone laid onto a geogrid and geotextile. Image from wikimedia commons

Stone mulch[edit]

Finer inorganic mulch materials can be of value applied in areas with extended ponding times i.e. in the the centre of recessed, bowl shaped bioretention, stormwater planters, trenches or swale practices. Inorganic mulches resist movement from flowing water and do not float. Applying a thin layer of inorganic mulch over the top of wood based mulch has been shown to reduce migration of the underlying layer by around 25% [6]. Inorganic mulches which may be available locally, include:

- Pea gravel

- River rock/beach stone

- Recycled glass

- Crushed mussel shells

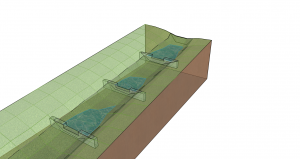

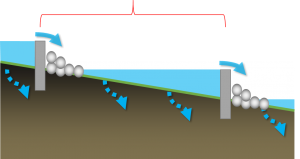

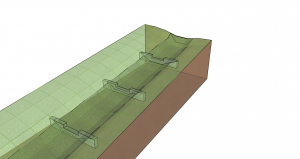

Check dams[edit]

Check dams are small dams or weirs constructed across a drainage ditch, swale, or channel to lower the speed of concentrated flows for a certain design range of storm events and to promote infiltration.

Check dams:

- may be constructed of any resilient and waterproof material, including: rock gabions, earth berms, coarse aggregate or rip-rap, concrete or metal. Stone used in check dams should have minimum median diameter 25 - 75 mm.

- for enhanced swales may be up to 0.6 m in height; the maximum design depth of ponded water should be ≤ 0.6 m.

- designed for higher flow velocities should have spillways incorporated into their profile, to direct water to the centre of the swale.

- are usually installed between 10 - 20 m along the swale. The spacing of dams should not exceed the horizontal distance from the toe of the upstream dam to the same elevation on the downstream dam.

- should have energy dissipation and erosion control measures installed in the 1 - 2 m downstream. Examples include large aggregate or turf reinforcement

Sizing and spacing of check dams[edit]

Check dams are a feature of enhanced grass swales. They promote infiltration and evaporation by promoting limited ponding. To design check dams into a swale:

- The height of each dam is determined by the depth of ponded water that will infiltrate in a specified period (often 48 - 72 hours). The infiltration may be through the turf grass or other plants directly into the native soil or some soil amendments may be proposed in the design.

- The gradient between the top of the lower check dam and the bottom of the upper one is called "compensation gradient" which is the future or final effective gradient of the swale. It is formed when material carried by flowing water fills the check dams to spillway level.

- Dams are usually installed between 10-20 m along the swale. The spaces between check dams can be determined according to the compensation gradient and the effective height of the dams. They are distributed such that the crest of each dam is at approximately the same elevation as the toe of the upstream dam. If the slope along the swale varies, so should the distance between the dams.

- The compensation gradient of enhanced swales must be < 1 % (0.5 % preferred).

The objective of these design recommendations are to maximize the distribution of ponded water along the whole BMP. Detailed design may require iteration of the dam heights and distances along each section of a long swale.

To estimate the depth of water that can be infiltrated into a surface within a given time:

Where:

- y = the depth of ponded water in mm,

- f' = the design infiltration rate in mm/hr (after correction, where required).

- t = time in hrs

After surveying the longitudinal profile of the swale, the number of check dams for the swale can be calculated by using the following equation:

Where:

- L: Length of swale (m)

- Si: Initial existing slope ratio of the swale (rise/run)

- Se: Desired effective slope of the enhanced swale (between 0.005 - 0.01, rise/run)

- h: The average effective height of the check dams in m (excluding foundations)(suggest you use y, calculated above)

- The first check dam should be constructed on a stable point in the gully such as a rock outcrop, the junction point of the gully to a road, the main stream or river, lake or reservoir.

- If there is no such stable point, a counter-dam must be constructed. The distance between the first dam and the counter-dam must be at least two times the effective height of the first check dam.

- The points where the ensuing check dams are to be built are determined according to the compensation gradient and the effective height of the check dams.

- The effective height of the second check dam is determined by taking into account the depth of the swale, the depth of the spillway and the maximum height of the check dam.

- In this way, all the other proposed check dam points can be calculated.

When spacing check dams, give preference to the narrowest parts of the swale in order to reduce construction costs. In this case, to establish the compensation gradient between the proposed check dams, proportionately increase the foundation depth of the upper check dam when the space between the lower and upper check dam is extended. When the space is shortened, decrease the foundation depth. As the foundation depth is increased, the total height of the check dam (effective height plus foundation depth) should not exceed the permissible, maximum total height.

Example Calculation[edit]

An enhanced swale of 42 m has an existing longitudinal slope of 6 %. The underlying soil has been amended to infiltrate at 16 mm/hr (after safety correction applied); the regulatory authority requires that ponded water must not remain for over 48 hours. The maximum height of the check dams (h) to prevent extended ponding is::

But the maximum recommended depth of check dams is 0.6 m (600 mm).

(As an aside, these will drain in )

The current vertical distance along the swale is::

The desired effective slope to slow flow is 0.5%. The vertical distance along the swale with compensation gradient is::

The number of check dams required is::

This is rounded up to 4 dams, creating 5 ponding zones::

So the four check dams will be 0.6 m high and spaced every 8.4 m along the swale. These are fairly close together, but this construction is achievable and the dimensions are not remarkable, given the change in gradient is an order of magnitude.

- ↑ Ontario Ministry of Transportation, & Ontario Ministry for Transportation. (2016). Stormwater Management Requirements for Land Development Proposals. Retrieved February 26, 2018, from http://www.mto.gov.on.ca/english/publications/drainage/stormwater/section8.shtml#controls

- ↑ Drainage and Hydrology Section Transportation Engienering Branch Quality and Standards Division. (1997). MTO Drainage Management Manual. Retrieved from http://www.ontla.on.ca/library/repository/mon/12000/198363.pdf

- ↑ 3.0 3.1 Oregon State Univ., Corvallis. Dept. of Civil, Construction and Environmental Engineering.; Environmental Protection Agency, Cincinnati ONRMRL. Storm Water Management Model Reference Manual Volume I Hydrology (Revised). 2016:233.https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P100NYRA.txt Accessed August 23, 2017.

- ↑ Ontario Provincial Standard Specification. (2014). Construction Specification and for Seed and Cover OPSS.PROV 804. Retrieved from http://www.raqsb.mto.gov.on.ca/techpubs/ops.nsf/0/3a785d2f480f9349852580820062910a/$FILE/OPSS.PROV 804 Nov2014.pdf

- ↑ Roger T. Kilgore and George K. Cotton, (2005) Design of Roadside Channels with Flexible Linings Hydraulic Engineering Circular Number 15, Third Edition https://www.fhwa.dot.gov/engineering/hydraulics/pubs/05114/05114.pdf

- ↑ Simcock, R and Dando, J. 2013. Mulch specification for stormwater bioretention devices. Prepared by Landcare Research New Zealand Ltd for Auckland Council. Auckland Council technical report, TR2013/056