Filtration Manufactured Treatment Devices

Revision as of 21:47, 6 February 2024 by DanielFilippi (talk | contribs) (Created page with "File:Upflow MTD.jpg|thumb|450px|Plan view of an upflow filtration MTD with filter cartridges. This example for the U.K provides four separate stages of treatment for influen...")

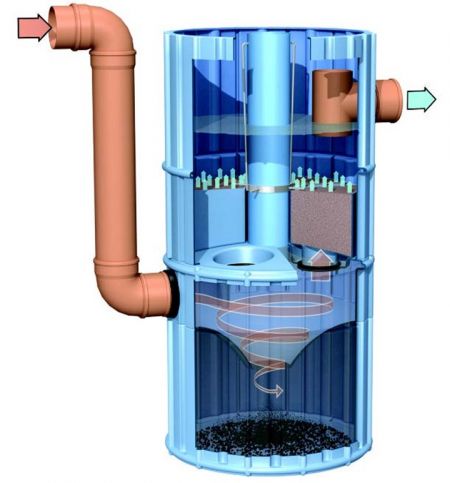

Plan view of an upflow filtration MTD with filter cartridges. This example for the U.K provides four separate stages of treatment for influent water including: 1) oil retention, 2) chemical separation, 3) filtration and 4) sedimentation (Source: 3P Technik UK Ltd, 2023)[1].

Overview[edit]

Filtration Manufactured Treatment Devices (MTDs) are structures with one or more chambers containing filtration media, membranes and/or filtration cartridges that remove solids and debris/trash from runoff. Some units may have oil separation functions and pretreatment chambers for coarse sediment and debris. The filter components are designed to remove the coarse and fine sediment fraction of suspended solids and associated pollutants in stormwater runoff and may also target removal of dissolved pollutants such as phosphorus or metals through biological and/or chemical processes.

Application[edit]

- ↑ 3P Technik UK Ltd, 2023. HYDROSYSTEM1000 SUDS MULTI-PROCESS TREATMENT DEVICE. Multi-process SUDS Treatment Device Stages. Accessed: https://www.3ptechnik.co.uk/stormwater-treatment/hydrosystem_1000/